Industry News

View All Products

en

When it comes to handling corrosive liquids, such as acids, alkalis, high-salinity solutions, or high-temperature fluids, selecting the right pump is crucial. These liquids can be highly reactive and damaging, making it essential to select a pump that can withstand their corrosive nature without compromising performance or safety. This is where the stainless steel pump comes into play.

Corrosive liquids pose significant challenges for industrial processes. Whether in chemical manufacturing, wastewater treatment, or pharmaceutical production, these fluids can quickly degrade materials that are not specifically designed to handle them. Traditional pumps made from materials like cast iron or standard carbon steel simply cannot withstand the harsh conditions. They corrode rapidly, to leaks, failures, and potential safety hazards. This is why a stainless steel pump is often the preferred choice.

Why Choose a Stainless Steel Pump?

A stainless steel pump is engineered to handle the demanding applications. Stainless steel is an alloy that combines iron with chromium, nickel, and other elements to create a material that is highly resistant to corrosion. This resistance is due to a thin, protective oxide layer that forms on the steel's surface. This layer prevents further oxidation and protects the underlying metal from corrosive attack.

Corrosion Resistance: Stainless steel pumps are designed to resist corrosion from a wide range of chemicals. This includes acids, alkalis, and salts, making them ideal for handling corrosive liquids. The alloy's composition ensures that it can withstand prolonged exposure to these substances without significant degradation.

Durability: Stainless steel is not only resistant to corrosion but also incredibly durable. It can handle high pressures and temperatures, making it suitable for a variety of industrial applications. This durability means that a stainless steel pump will have a longer service life compared to pumps made from less resistant materials.

Hygienic and Cleanable: In industries where hygiene is critical, such as food processing or pharmaceuticals, stainless steel pumps are preferred. They are easy to clean and sanitize, ensuring that they meet the standards of cleanliness.

Cost-Effective: While the initial cost of a stainless steel pump may be higher than that of a pump made from cheaper materials, the long-term benefits are significant. Stainless steel pumps require less maintenance, have a longer lifespan, and are less likely to fail, reducing overall operational costs.

Key Features of Stainless Steel Pumps

When selecting a stainless steel pump for corrosive liquids, there are several key features to consider:

Material Grade: Not all stainless steel is created equal. Different grades of stainless steel offer varying levels of corrosion resistance. For example, 316 stainless steel is often preferred for its resistance to chloride corrosion, making it ideal for handling seawater or other high-salinity solutions.

Seal Design: The seals in a stainless steel pump are crucial for preventing leaks and ensuring that corrosive liquids do not escape. High-quality seals made from materials like Teflon or Viton are often used to provide long-lasting protection.

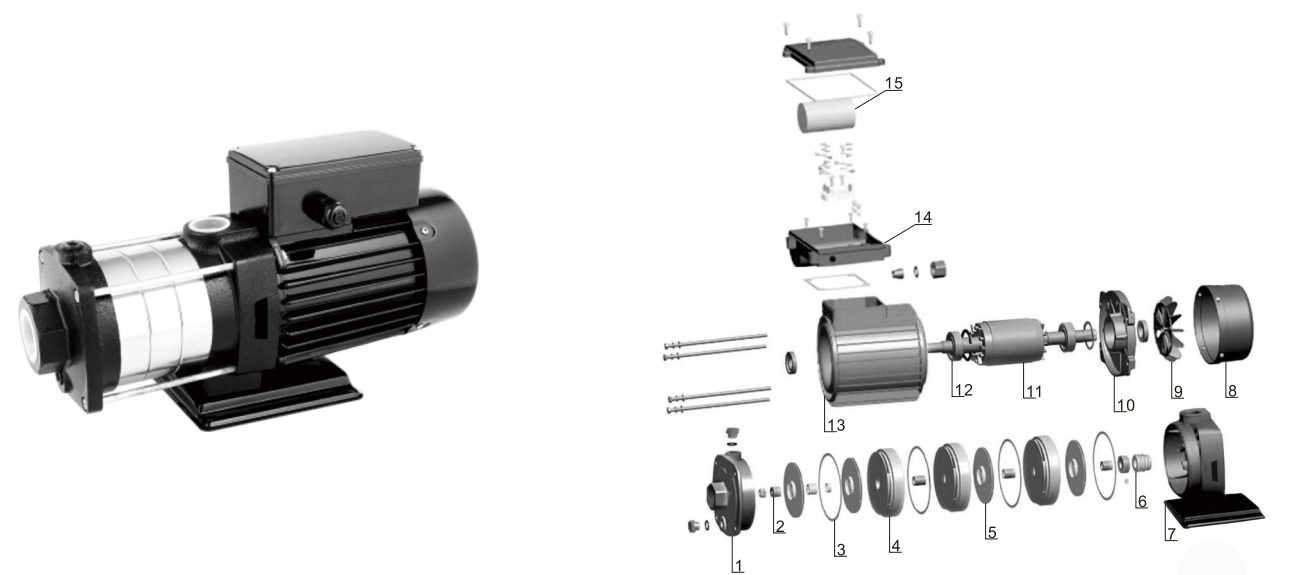

Motor and Drive: The motor and drive system of a stainless steel pump must also be designed to withstand harsh conditions. Enclosed and corrosion-resistant motors are essential to ensure reliable operation.

Flow and Pressure Ratings: Depending on the specific application, the flow rate and pressure capabilities of the pump must be carefully considered. Stainless steel pumps are available in a wide range of sizes and configurations to meet different needs.

Applications of Stainless Steel Pumps

Stainless steel pumps are used in a variety of industries where corrosive liquids are common. Some typical applications include:

Chemical Processing: In the chemical industry, stainless steel pumps are used to transfer and process a wide range of corrosive chemicals. Their ability to withstand acids, alkalis, and solvents makes them indispensable.

Wastewater Treatment: Wastewater often contains corrosive substances, including acids, alkalis, and salts. Stainless steel pumps are used to move and treat this water, ensuring that the treatment process runs smoothly and safely.

Pharmaceuticals: In pharmaceutical manufacturing, hygiene and cleanliness are paramount. Stainless steel pumps are used to handle and process various liquids, ensuring that they meet the strict standards required in this industry.

Food and Beverage: In the food and beverage industry, stainless steel pumps are used to handle products like fruit juices, dairy products, and other liquids. Their hygienic design and corrosion resistance make them the ideal choice.

Maintenance and Care

While stainless steel pumps are highly durable, proper maintenance is still essential to ensure their longevity and performance. Regular inspections should be conducted to check for signs of wear or corrosion. Seals and gaskets should be replaced as needed, and the pump should be cleaned according to the manufacturer's recommendations. By following these maintenance practices, a stainless steel pump can provide reliable service for many years.

When dealing with corrosive liquids, choosing the right pump is crucial. A stainless steel pump offers unparalleled corrosion resistance, durability, and reliability. Its ability to handle a wide range of chemicals, high temperatures, and pressures makes it the ideal choice for many industrial applications. Whether you are in the chemical, wastewater, pharmaceutical, or food and beverage industry, a stainless steel pump can provide the performance and safety you need. By understanding the key features and benefits of stainless steel pumps, you can make an informed decision that will ensure your processes run smoothly and safely.