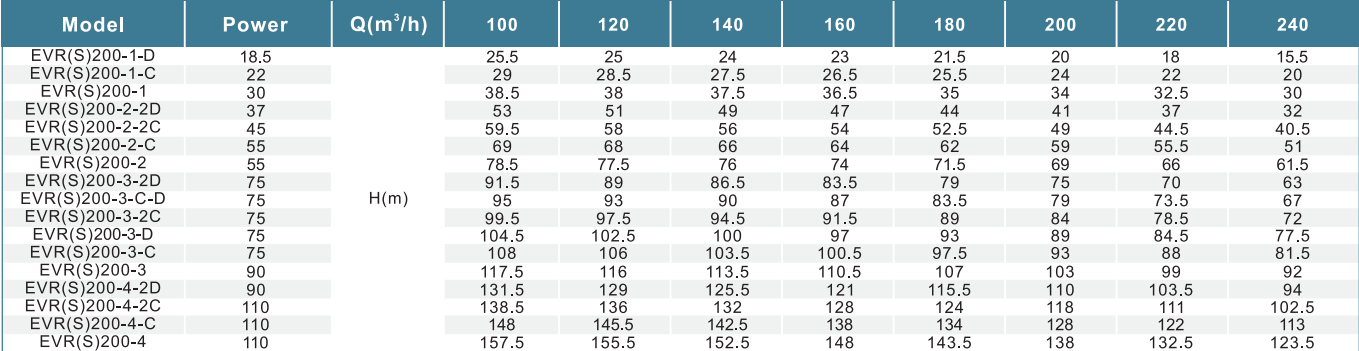

EVR(S) Series Water Shortage Protection Voltage Stabilization Stainless Steel Vertical Multistage Pump

View All Products

en

Water Shortage Protection

Voltage Stabilization

Stainless Steel Construction

Vertical Multistage Design

Easy Maintenance

The EVR(S) Series Water Shortage Protection Voltage Stabilization Stainless Steel Vertical Multistage Pump is a type of pump designed for various water applications. Its key features include water shortage protection and voltage stabilization, making it suitable for areas with unstable power supply or fluctuating water availability. The pump is constructed with stainless steel, which offers durability and resistance to corrosion, making it ideal for water-related environments. The vertical multistage design allows for efficient pumping of water at high pressures. If you need more specific information about this pump or have any other questions, feel free to ask!

1、Water Shortage Protection : The pump is equipped with water shortage protection features, which help prevent damage to the pump in case of low water levels or water supply interruptions. This ensures the longevity and reliability of the pump in water-scarce environments.

2、Voltage Stabilization : The pump is designed to provide voltage stabilization, ensuring consistent and reliable performance even in areas with fluctuating power supply. This feature helps protect the pump and other connected equipment from voltage surges or drops.

3、Stainless Steel Construction : The pump is constructed with stainless steel materials, including the pump casing, impellers, and other components. Stainless steel offers excellent corrosion resistance, ensuring the longevity and durability of the pump in various environments.

4、Vertical Multistage Design : The pump features a vertical multistage design, which allows for high-pressure water movement and efficient performance. It is designed to handle high-pressure applications and provide consistent water flow.

5、Easy Maintenance : The pump is designed for easy maintenance, with accessible components and a user-friendly design. This allows for quick and hassle-free servicing, reducing downtime and maintenance costs.

|

Materials Table |

|||

|

NO. |

Part |

Material |

Optional Material |

|

1 |

Base plate |

ADC12 |

ZG304 |

|

2 |

Drainage plug assembly |

AISI304 |

AISI316 |

|

3 |

Chasis |

ZG304 |

ZG316 |

|

4 |

Primary diffuser |

AISI304 |

|

|

5 |

Medium diffuser |

AISI304 |

AISI316 |

|

6 |

Diffuser with bearing |

AISI304 |

AISI316 |

|

7 |

Impeller |

AISI304 |

AISI316 |

|

8 |

Final volute |

AISI304 |

AISI316 |

|

9 |

Filling plug |

AISI304 |

AISI316 |

|

10 |

Motor base |

HT200 |

|

|

11 |

Coupling |

Iron based powder metallurgy |

|

|

12 |

Motor |

|

|

|

13 |

Guarding plate |

AISI304 |

|

|

14 |

Cartridge seal |

|

|

|

15 |

Vent plug assembly |

AISI304 |

AISI316 |

|

16 |

Pump cover |

ZG304 |

ZG316 |

|

17 |

Pump shaft |

AISI316 |

|

|

18 |

Pump barrel |

AISI304 |

AISI316 |

|

19 |

Flange |

ZG35 |

|

|

Materials Table |

|||

|

NO. |

Part |

Material |

Optional Material |

|

1 |

Base plate |

ADC12 |

ZG304 |

|

2 |

Drainage plug assembly |

AISI304 |

AISI316 |

|

3 |

Chasis |

ZG304 |

ZG316 |

|

4 |

Primary diffuser |

AISI304 |

|

|

5 |

Medium diffuser |

AISI304 |

AISI316 |

|

6 |

Diffuser with bearing |

AISI304 |

AISI316 |

|

7 |

Impeller |

AISI304 |

AISI316 |

|

8 |

Final volute |

AISI304 |

AISI316 |

|

9 |

Filling plug |

AISI304 |

AISI316 |

|

10 |

Motor base |

HT200 |

|

|

11 |

Coupling |

Iron based powder metallurgy |

|

|

12 |

Motor |

|

|

|

13 |

Guarding plate |

AISI304 |

|

|

14 |

Cartridge seal |

|

|

|

15 |

Vent plug assembly |

AISI304 |

AISI316 |

|

16 |

Pump cover |

ZG304 |

ZG316 |

|

17 |

Pump shaft |

AISI316 |

|

|

18 |

Pump barrel |

AISI304 |

AISI316 |

|

19 |

Flange |

ZG35 |

|

|

Materials Table |

|||

|

NO. |

Part |

Material |

Optional Material |

|

1 |

Base plate |

HT200 |

ZG304 |

|

2 |

Flange |

ZG35 |

|

|

3 |

Chasis |

ZG304 |

ZG316 |

|

4 |

Primary diffuser |

AISI304 |

|

|

5 |

Medium diffuser |

AISI304 |

AISI316 |

|

6 |

Diffuser with bearing |

AISI304 |

AISI316 |

|

7 |

Impeller |

AISI304 |

AISI316 |

|

8 |

Shaft sleeve assembly |

|

|

|

9 |

Final diffuser |

AISI304 |

AISI316 |

|

10 |

Vent plug assembly |

AISI304 |

AISI316 |

|

11 |

Motor base |

HT200 |

|

|

12 |

Motor |

|

|

|

13 |

Guarding plate |

AISI304 |

|

|

14 |

Coupling |

QT400 |

|

|

15 |

Cartridge seal |

|

|

|

16 |

Pump head |

ZG304 |

ZG316 |

|

17 |

Filling plug |

AISI304 |

AISI316 |

|

18 |

Tension plate |

AISI304 |

AISI316 |

|

19 |

Pump barrel |

AISI304 |

AISI316 |

|

20 |

Pump shaft |

AISI304 |

AISI316 |

|

erials Table |

|||

|

NO. |

Part |

Material |

Optional Material |

|

1 |

Base plate |

HT200 |

ZG304 |

|

2 |

Flange |

ZG35 |

|

|

3 |

Chasis |

ZG304 |

ZG316 |

|

4 |

Primary diffuser |

AISI304 |

|

|

5 |

Medium diffuser |

AISI304 |

AISI316 |

|

6 |

Diffuser with bearing |

AISI304 |

AISI316 |

|

7 |

Impeller |

AISI304 |

AISI316 |

|

8 |

Final diffuser |

AISI304 |

AISI316 |

|

9 |

Vent plug assembly |

AISI304 |

AISI316 |

|

10 |

Motor base |

HT200 |

|

|

11 |

Motor |

|

|

|

12 |

Guarding plate |

AISI304 |

|

|

13 |

Coupling |

QT400 |

|

|

14 |

Cartridge seal |

|

|

|

15 |

Filling plug |

AISI304 |

AISI316 |

|

16 |

Tension plate |

AISI304 |

AISI316 |

|

17 |

Pump barrel |

AISI304 |

AISI316 |

|

18 |

Pump shaft |

AISI304 |

AISI316 |

A borehole pump manufacturer plays an important role in water supply systems, especially in areas where surface water is...

READ MOREWater drawn from deep underground plays a key role in agriculture, industry, and residential supply. Behind this process...

READ MOREEfficient irrigation plays a key role in modern agriculture, landscaping, and water management projects. An experienced ...

READ MORE

Starting pressure : 1.2bar - 3.0barMax. Rated Current : 10AMax. Allowable Press...

See Details

Starting pressure : 1.2bar - 2.2bar Max. Rated Current : 30A Max. Working Press...

See Details

Carbon steel flange Working temperature: -10°C~99°C (Butyl) -10°C~99°C (EPDM) 0°...

See Details

Replaceable membrane pressure tanksCarbon steel flangeWorking temperature : -10°...

See Details

Low Noise High Quality Extensively used High efficient running

See Details

Copper winding Built-in thermal protector Stainless steel welded shaft Impeller:...

See Details

serieswatershortageprotectionvoltagestabilizationstainlesssteelverticalmultistagepump-1.jpg)

serieswatershortageprotectionvoltagestabilizationstainlesssteelverticalmultistagepump.jpg)