4ST Series 4 inch Stainless Steel Construction Electric Water Pump for Deep Well

View All Products

en

The 4ST Series 4 inch Stainless Steel Construction Electric Water Pump for Deep Well is a specialized pump designed for deep well applications. It is known for its stainless steel construction, powerful motor, and reliable performance.

One of the key features of this deep well pump is its stainless steel construction. Stainless steel is a durable and corrosion-resistant material, making it ideal for use in deep well environments where the pump is exposed to water and potentially corrosive elements. The stainless steel construction ensures the pump's longevity and reliable performance, even in challenging conditions.

The pump is equipped with a powerful motor, providing sufficient power to pump water from considerable depths. This makes it suitable for applications such as residential water supply, irrigation, or industrial use.

The 4-inch size of the pump allows for easy installation in standard-sized wells. It is designed to efficiently extract water from deep underground sources and deliver it to the surface.

Additionally, these pumps may feature built-in thermal protection mechanisms to prevent motor overheating. This helps to prolong the pump's lifespan and ensures safe operation.

The 4ST Series 4 inch Stainless Steel Construction Electric Water Pump for Deep Well is a reliable and efficient solution for deep well applications. Its stainless steel construction, powerful motor, and thermal protection features make it suitable for extracting water from deep underground sources with efficiency and durability.

(according to our general sales conditions)

|

Components |

Material |

|

Delivery casing |

AISI 304 SS |

|

Suction lantern |

AISI 304 SS |

|

Diffuser |

AISI 304 SS |

|

Impeller |

AISI 304 SS |

|

Shaft |

AISI 304 SS |

|

Shaft coupling |

AISI 304 SS |

|

Wear ring |

Rubber |

|

Motor external casing |

AISI 304 SS |

|

Top chock |

|

|

Cast-iron ASTM NO.30 |

|

|

Bottom support |

Cast-iron ASTM NO.30 |

|

Seal |

NBR Graphite-SIC/TC |

|

Shaft |

AISI 304 SS-ASTM 5140 |

|

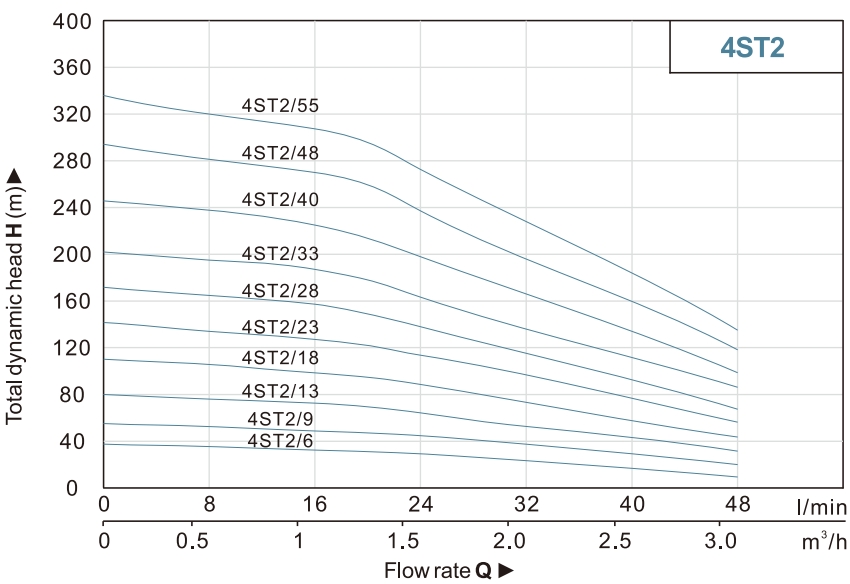

Model |

Power |

Deliver |

|||||||||

|

1~220-240V |

3~380-415V |

KW |

HP |

Q(m³/h) |

0 |

0.5 |

1 |

1.5 |

2 |

2.5 |

3 |

|

Q(l/min) |

0 |

8 |

16 |

24 |

32 |

40 |

48 |

||||

|

4STM2/6 |

4ST2/6 |

0.37 |

0.5 |

H(m) |

37 |

35 |

34 |

30 |

24 |

20 |

15 |

|

4STM2/9 |

4ST2/9 |

0.37 |

0.5 |

55 |

51 |

48 |

45 |

36 |

30 |

20 |

|

|

4STM2/13 |

4ST2/13 |

0.55 |

0.75 |

80 |

76 |

72 |

64 |

52 |

44 |

31 |

|

|

4STM2/18 |

4ST2/18 |

0.75 |

1 |

110 |

106 |

99 |

89 |

73 |

66 |

43 |

|

|

4STM2/23 |

4ST2/23 |

1.1 |

1.5 |

141 |

134 |

127 |

114 |

92 |

77 |

56 |

|

|

4STM2/28 |

4ST2/28 |

1.5 |

2 |

171 |

162 |

158 |

139 |

112 |

94 |

68 |

|

|

4STM2/33 |

4ST2/33 |

1.5 |

2 |

202 |

195 |

187 |

163 |

132 |

111 |

87 |

|

|

4STM2/40 |

4ST2/40 |

2.2 |

3 |

245 |

238 |

225 |

198 |

160 |

135 |

99 |

|

|

4STM2/48 |

4ST2/48 |

2.2 |

3 |

294 |

278 |

270 |

237 |

192 |

161 |

119 |

|

|

4STM2/55 |

4ST2/55 |

3 |

4 |

336 |

320 |

308 |

272 |

220 |

185 |

135 |

|

|

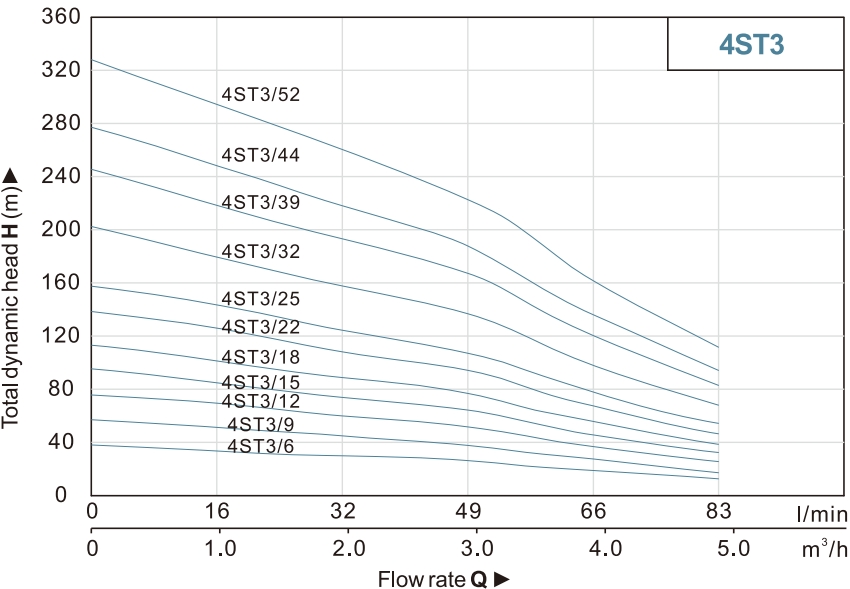

Model |

Power |

Deliver |

|||||||||

|

1~220-240V |

3~380-415V |

KW |

HP |

Q(m³/h) |

0 |

1.2 |

2 |

3 |

3.6 |

4 |

4.8 |

|

Q(l/min) |

0 |

20 |

33 |

50 |

60 |

67 |

80 |

||||

|

4STM3/6 |

4ST3/6 |

0.37 |

0.5 |

H(m) |

38 |

33 |

30 |

26 |

21 |

19 |

13 |

|

4STM3/9 |

4ST3/9 |

0.55 |

0.75 |

57 |

50 |

45 |

38 |

31 |

28 |

19 |

|

|

4STM3/12 |

4ST3/12 |

0.75 |

1 |

76 |

68 |

60 |

51 |

42 |

37 |

26 |

|

|

4STM3/15 |

4ST3/15 |

1.1 |

1.5 |

95 |

82 |

74 |

64 |

53 |

46 |

32 |

|

|

4STM3/18 |

4ST3/18 |

1.1 |

1.5 |

113 |

98 |

89 |

77 |

63 |

56 |

39 |

|

|

4STM3/22 |

4ST3/22 |

1.5 |

2 |

139 |

122 |

109 |

94 |

78 |

68 |

47 |

|

|

4STM3/25 |

4ST3/25 |

1.5 |

2 |

158 |

140 |

124 |

107 |

90 |

78 |

54 |

|

|

4STM3/32 |

4ST3/32 |

2.2 |

3 |

202 |

175 |

158 |

137 |

114 |

99 |

68 |

|

|

4STM3/39 |

4ST3/39 |

3 |

4 |

246 |

213 |

193 |

167 |

139 |

121 |

83 |

|

|

4STM3/44 |

4ST3/44 |

3 |

4 |

277 |

242 |

218 |

188 |

154 |

136 |

94 |

|

|

4STM3/52 |

4ST3/52 |

4 |

5.5 |

328 |

282 |

257 |

222 |

189 |

161 |

111 |

|

|

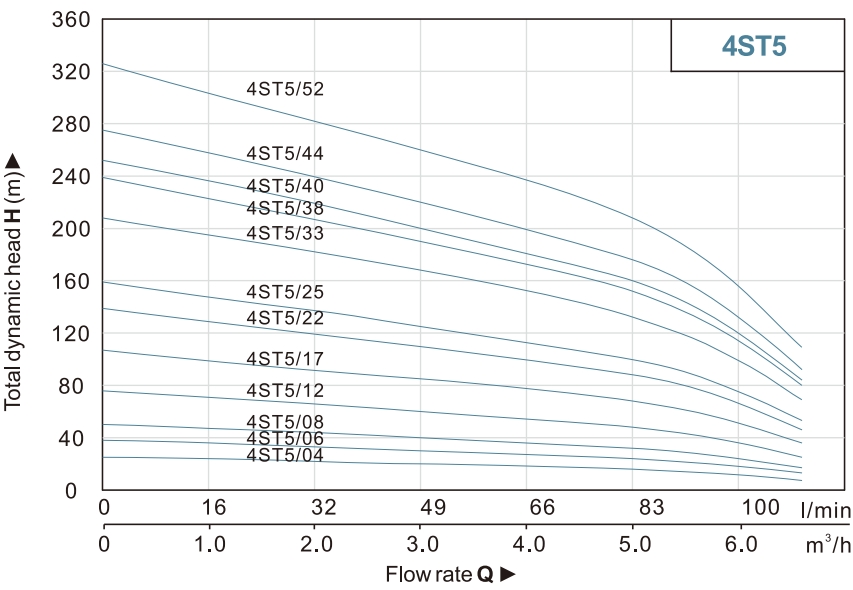

Model |

Power |

Deliver |

|||||||||

|

1~220-240V |

3~380-415V |

KW |

HP |

Q(m³/h) |

0 |

1 |

2 |

3 |

5 |

6 |

6.6 |

|

Q(l/min) |

0 |

16.6 |

33.2 |

49.8 |

83 |

99.6 |

109.5 |

||||

|

4STM5/04 |

4ST5/04 |

0.37 |

0.5 |

H(m) |

25 |

24 |

22 |

20 |

16 |

12 |

8 |

|

4STM5/06 |

4ST5/06 |

0.55 |

0.75 |

38 |

36 |

33 |

30 |

24 |

18 |

13 |

|

|

4STM5/08 |

4ST5/08 |

0.75 |

1 |

50 |

47 |

44 |

40 |

32 |

24 |

17 |

|

|

4STM5/12 |

4ST5/12 |

1.1 |

1.5 |

76 |

72 |

67 |

60 |

48 |

36 |

25 |

|

|

4STM5/17 |

4ST5/17 |

1.5 |

2 |

107 |

99 |

91 |

85 |

68 |

51 |

36 |

|

|

4STM5/22 |

4ST5/22 |

2.2 |

3 |

139 |

130 |

122 |

110 |

88 |

66 |

46 |

|

|

4STM5/25 |

4ST5/25 |

2.2 |

3 |

159 |

145 |

137 |

125 |

100 |

75 |

53 |

|

|

4STM5/33 |

4ST5/33 |

3 |

4 |

208 |

192 |

182 |

165 |

132 |

99 |

69 |

|

|

4STM5/38 |

4ST5/38 |

4 |

5.5 |

239 |

220 |

209 |

190 |

152 |

114 |

80 |

|

|

4STM5/40 |

4ST5/40 |

4 |

5.5 |

252 |

241 |

223 |

200 |

160 |

120 |

84 |

|

|

4STM5/44 |

4ST5/44 |

4 |

5.5 |

275 |

259 |

242 |

220 |

176 |

132 |

92 |

|

|

4STM5/52 |

4ST5/52 |

5.5 |

7.5 |

326 |

302 |

287 |

260 |

208 |

156 |

109 |

|

|

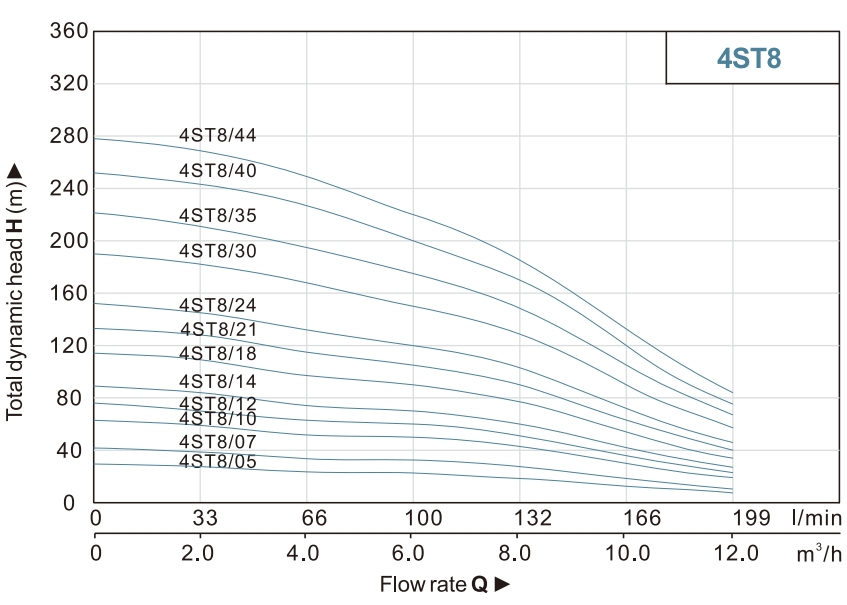

Model |

Power |

Deliver |

|||||||||

|

1~220-240V |

3~380-415V |

KW |

HP |

Q(m³/h) |

0 |

2 |

4 |

6 |

8 |

10 |

12 |

|

Q(l/min) |

0 |

33 |

66 |

100 |

133 |

166 |

199 |

||||

|

4STM8/05 |

4ST8/05 |

0.75 |

1 |

H(m) |

32 |

30 |

26 |

25 |

21 |

15 |

10 |

|

4STM8/07 |

4ST8/07 |

1.1 |

1.5 |

44 |

41 |

36 |

35 |

30 |

21 |

13 |

|

|

4STM8/10 |

4ST8/10 |

1.5 |

2 |

63 |

59 |

52 |

50 |

43 |

30 |

19 |

|

|

4STM8/12 |

4ST8/12 |

2.2 |

3 |

76 |

70 |

63 |

60 |

51 |

36 |

23 |

|

|

4STM8/14 |

4ST8/14 |

2.2 |

3 |

89 |

84 |

74 |

70 |

60 |

42 |

27 |

|

|

4STM8/18 |

4ST8/18 |

3 |

4 |

114 |

109 |

95 |

90 |

77 |

54 |

34 |

|

|

4STM8/21 |

4ST8/21 |

4 |

5.5 |

133 |

128 |

115 |

105 |

90 |

63 |

40 |

|

|

4STM8/24 |

4ST8/24 |

4 |

5.5 |

152 |

145 |

132 |

120 |

103 |

72 |

46 |

|

|

4STM8/30 |

4ST8/30 |

5.5 |

7.5 |

190 |

183 |

166 |

150 |

129 |

90 |

57 |

|

|

4STM8/35 |

4ST8/35 |

5.5 |

7.5 |

221 |

211 |

192 |

175 |

150 |

105 |

67 |

|

|

4STM8/40 |

4ST8/40 |

7.5 |

10 |

125 |

243 |

228 |

200 |

172 |

120 |

76 |

|

|

4STM8/44 |

4ST8/44 |

7.5 |

10 |

278 |

268 |

243 |

220 |

189 |

132 |

84 |

|

|

Model |

Power |

Deliver |

|||||||||

|

1~220-240V |

3~380-415V |

KW |

HP |

Q(m³/h) |

0 |

6 |

8 |

10 |

14 |

16 |

18 |

|

Q(l/min) |

0 |

100 |

133 |

166 |

232 |

257 |

299 |

||||

|

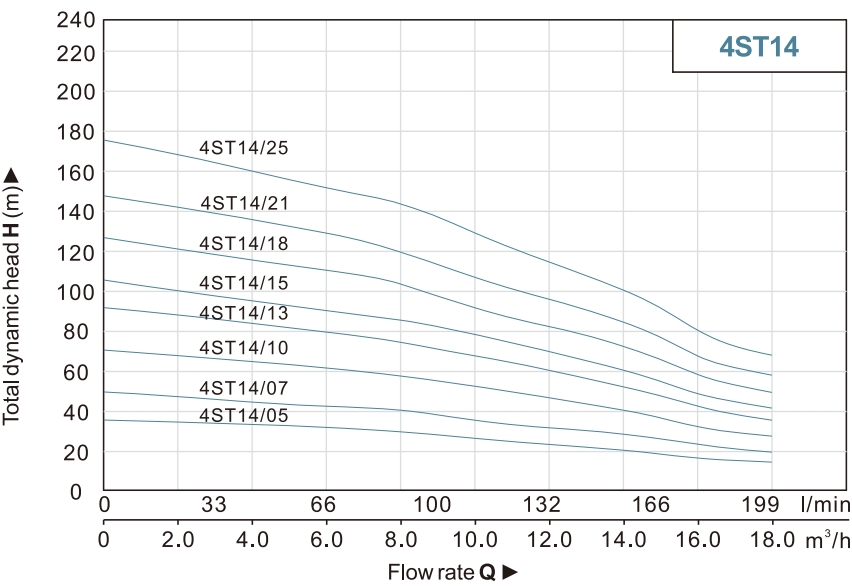

4STM14/05 |

4ST14/05 |

1.5 |

2 |

H(m) |

35 |

31 |

29 |

26 |

20 |

16 |

14 |

|

4STM14/07 |

4ST14/07 |

2.2 |

3 |

49 |

42 |

40 |

35 |

28 |

23 |

19 |

|

|

4STM14/10 |

4ST14/10 |

3 |

4 |

70 |

60 |

57 |

51 |

40 |

32 |

27 |

|

|

4STM14/13 |

4ST14/13 |

4 |

5.5 |

91 |

79 |

74 |

67 |

52 |

42 |

35 |

|

|

4STM14/15 |

4ST14/15 |

5.5 |

7.5 |

105 |

89 |

85 |

76 |

60 |

48 |

41 |

|

|

4STM14/18 |

4ST14/18 |

5.5 |

7.5 |

126 |

110 |

103 |

91 |

72 |

58 |

49 |

|

|

4STM14/21 |

4ST14/21 |

7.5 |

10 |

147 |

128 |

119 |

106 |

84 |

67 |

55 |

|

|

4STM14/25 |

4ST14/25 |

7.5 |

10 |

175 |

151 |

143 |

129 |

100 |

80 |

65 |

|

A borehole pump manufacturer plays an important role in water supply systems, especially in areas where surface water is...

READ MOREWater drawn from deep underground plays a key role in agriculture, industry, and residential supply. Behind this process...

READ MOREEfficient irrigation plays a key role in modern agriculture, landscaping, and water management projects. An experienced ...

READ MORE

Water Shortage Protection Pressure range : 20-100psi Rated Current : 12A Rated ...

See Details

Pressure Switch for Water Pump Pressure range : 0.5-3.5 BAR Rated Current : 4A ;...

See Details

Starting pressure : 1.2bar - 3.0bar Max. Rated Current : 10A Max. Allowable Pres...

See Details

Starting pressure : 1.2bar - 3.0bar Max. Rated Current : 10A Max. Working Pressu...

See Detailsaseriesnoisereductiondesignacid-baseverticalsurfacepump-1.jpg)

Identify noise sourcesAnalyze the operating conditionsUse noise reduction techni...

See Details

High Pressure Hot And Cold Water Circulation Pump Inlet/Outlet: 1.5" x 1.5" Body...

See Details