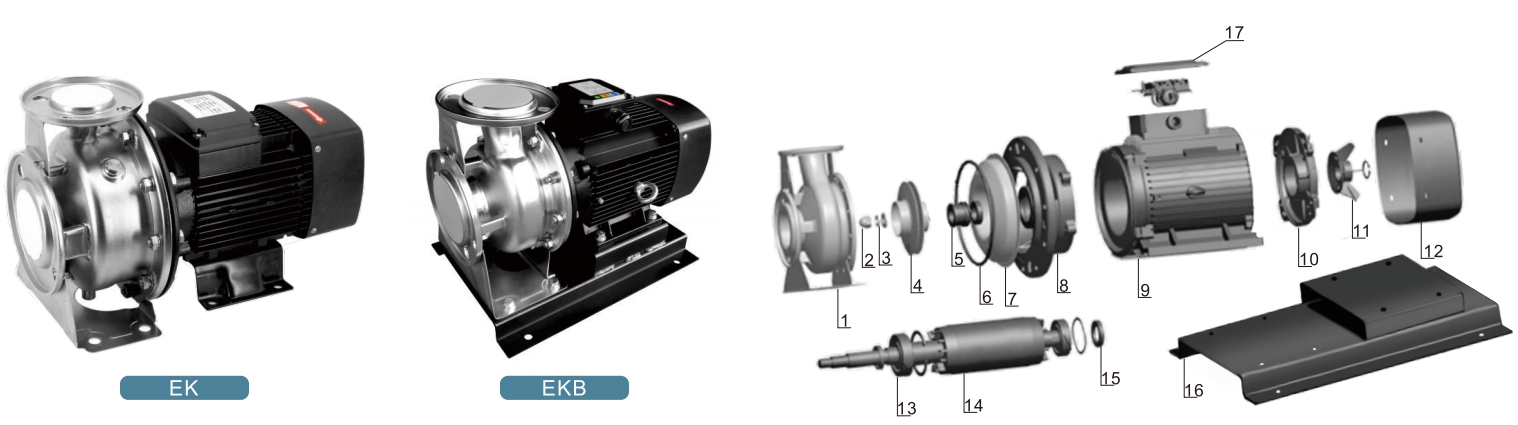

EK (B) Series End-Suction Precision-engineered Body Centrifugal Pump

View All Products

en

All-copper motors

end-suction pump

Precision-engineered body design

EK(B) series horizontal stainless steel single-stage end-suctioni centrifugal pump: axial inlet and radial outlet. Motor drawn out from pump design is easy to disassemble the motor and impeller without disassembling the pump casing and pipe line. dopt advanced manufacture technic as stainless steel by cold pressing, hydroforming, welding and etc. It is the innovated new structure centrifugal pump. It can replace the traditional IS pumps and general corrosion resistance pumps. It is equipped with a special motor for the lengthening shaft, which is a fully enclosed air-cooled motor. The pump casing, pump cover, impeller, shaft and other flow passage components are made of SUS304 material, and SUS316 material can be configured as required. It is characterized by light structure, high efficiency and energy saving, light corrosion resistance, durability, low noise, etc.It is suitable for water dawn from depths and through long pipes .

1. All-copper motors : Utilizing 800 cold-rolled silicon steel stators, our pumps are designed to safeguard against card machine damage and ensure the durability of the motor.

2. End suction pump : Prior to activation, the pump is filled with water to enable direct use with the water already inside the pump housing.

3. Precision-engineered body design, encompassing features such as wiring protection boxes and motor fan heating systems, have been incorporated to enhance the practicality of our product.

4. Fluorine rubber mechanical seals provide exceptional resistance to high temperatures and wear.

5. Our product comes with a one-year warranty. Should you encounter any issues during this time, please feel free to contact us for assistance.

|

Materials Table |

||

|

NO. |

Part |

Material |

|

1 |

Pump Body |

Stainless steel |

|

2 |

Hexagonal Nut |

|

|

3 |

Spring Washer |

|

|

4 |

Impeller |

HT200/06Cr19Ni10 |

|

5 |

Mechanical Seal |

|

|

6 |

“O”-ring |

NBR |

|

7 |

Support Cover |

06Cr19Ni10 |

|

8 |

Support |

HT200 |

|

9 |

Stator |

|

|

10 |

Rear cover |

ZL102 |

|

11 |

Fan |

PP |

|

12 |

Fan Cover |

08F |

|

13 |

Bearing |

|

|

14 |

Rotor |

|

|

15 |

Oil Seal |

|

|

16 |

Base |

|

|

17 |

Terminal Cover |

08F |

| Model | Power(P2) | Rated head | Rated flow | (Amps) | Weight | |

| KW | (m) | (m3 /h) | 220V/50Hz | 380V/50Hz | kg | |

| EK(B)50-32-160/1.1(T) | 1.1 | 18.5 | 12.5 | 7.0 | 2.6 | 21.5/26.5 |

| EK(B)50-32-160/1.5(T) | 1.5 | 22 | 12.5 | 9.2 | 3.5 | 22.5/27.5 |

| EK(B)50-32-160/2.2(T) | 2.2 | 26 | 12.5 | 14 | 4.9 | 31/37.5 |

| EK(B)50-32-200/3.0T | 3.0 | 32 | 12.5 | 6.3 | 38/45 | |

| EK(B)50-32-200/4.0T | 4.0 | 43 | 12.5 | 9.6 | 54/61.2 | |

| EK(B)50-32-200/5.5T | 5.5 | 52.5 | 12.5 | 11.1 | 62.3/70.5 | |

| EK(B)50-32-200/7.5T | 7.5 | 62.5 | 12.5 | 14.9 | 73.8/82 | |

| EK(B)65-40-125/1.5(T) | 1.5 | 14.5 | 25 | 9.2 | 3.5 | 21/26.5 |

| EK(B)65-40-125/2.2(T) | 2.2 | 21 | 25 | 14 | 4.9 | 29/42 |

| EK(B)65-40-125/3.0T | 3.0 | 25.5 | 25 | 6.3 | 37/43.6 | |

| EK(B)65-40-160/4.0T | 4.0 | 32 | 25 | 9.6 | 49.5/56.5 | |

| EK(B)65-40-200/5.5T | 5.5 | 42.5 | 25 | 11.1 | 62.5/70.7 | |

| EK(B)65-40-200/7.5T | 7.5 | 48 | 25 | 14.9 | 74/82.2 | |

| EK(B)65-40-200/11T | 11 | 70 | 25 | 21.2 | 93/107 | |

| EK(B)65-50-125/3.0T | 3.0 | 18 | 40 | 6.3 | 37.5/44 | |

| EK(B)65-50-125/4.0T | 4.0 | 21 | 40 | 9.6 | 49.5/56.5 | |

| EK(B)65-50-160/5.5T | 5.5 | 26.5 | 50 | 11.1 | 62.5/70.7 | |

| EK(B)65-50-200/7.5T | 7.5 | 33.5 | 50 | 14.9 | 73/81.2 | |

| EK(B)65-50-200/9.2T | 9.2 | 39 | 50 | 18.3 | 82/96 | |

| EK(B)65-50-200/11T | 11 | 48 | 50 | 21.2 | 93/107 | |

| EK(B)65-50-200/15T | 15 | 62 | 50 | 28.6 | 107/121 | |

| EK(B)65-50-200/18.5T | 18.5 | 67 | 50 | 34.7 | 158/180.4 | |

| EK(B)80-65-125/4.0T | 4.0 | 11 | 80 | 9.6 | 49.5/57.3 | |

| EK(B)80-65-125/5.5T | 5.5 | 13 | 100 | 11.1 | 62.5/74.5 | |

| EK(B)80-65-125/7.5T | 7.5 | 20 | 100 | 14.9 | 69.5/81.5 | |

| EK(B)80-65-125/9.2T | 9.2 | 25 | 100 | 18.3 | 80.5/94.5 | |

| EK(B)80-65-160/11T | 11 | 28.5 | 100 | 21.2 | 93/107 | |

| EK(B)80-65-160/15T | 15 | 35.5 | 100 | 28.6 | 107/121 | |

| EK(B)80-65-200/18.5T | 18.5 | 45 | 100 | 34.7 | 158/182.3 | |

| EK(B)80-65-200/22T | 22 | 52 | 100 | 41.0 | 192/231.4 | |

A borehole pump manufacturer plays an important role in water supply systems, especially in areas where surface water is...

READ MOREWater drawn from deep underground plays a key role in agriculture, industry, and residential supply. Behind this process...

READ MOREEfficient irrigation plays a key role in modern agriculture, landscaping, and water management projects. An experienced ...

READ MORE

Max. Rated Current : 10A Max. Allowable Pressure : 10bar Rated Voltage : 100V-12...

See Details

Starting pressure : 1.2bar - 3.0bar Max. Rated Current : 10A Max. Working Pressu...

See Details

Carbon steel flange Working temperature: -10°C~99°C (Butyl) -10°C~99°C (EPDM) 0°...

See Details

Max. pressure :6bar-16bar Working temperature: -20°C~99°C (Butyl) -20°C~99°C (EP...

See Details

Fixed membrane expansion tanks Working temperature: -20°C~99°C Tank for heating ...

See Details

High Pressure Hot And Cold Water Circulation Pump Inlet/Outlet: 1.5" x 1.5" Body...

See Details