3.5SDM2 Double Rings Hole Design Stainless Steel Thickened Base Borehole Submersible Pump

View All Products

en

The 3.5SDM2 Borehole Submersible Pump is a reliable and efficient water pumping solution designed for borehole applications. It allows for efficient water flow and reduces energy consumption, ensuring optimal water extraction from boreholes.. Its durable construction, submersible design, and user-friendly operation make it a dependable choice for extracting water from boreholes.

Key Features :

1、This pump features a double rings hole design and a stainless steel thickened base, ensuring durability and long-lasting performance.The double rings hole design enhances the pump's efficiency and performance.

4、 Maximum fluid temperature up to +35℃

Maximum sand content : 0.25%

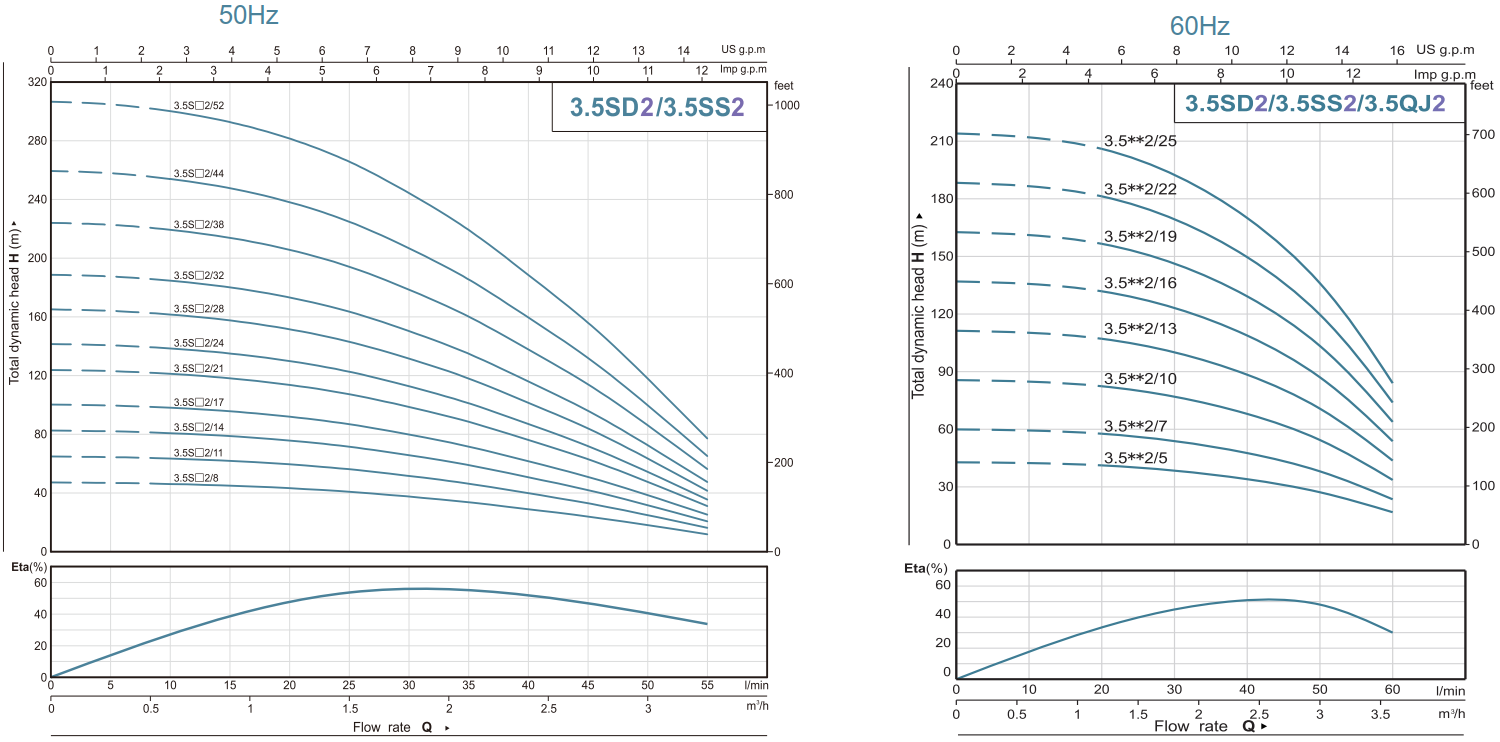

Minimum well diameter : 3.5"

5、Metal motor : Single-phase:220-240V/50Hz or Three-phase:380-415V/50Hz

6、Furnished with a start control box or a digital automatic control box.

7、Pumps are designed by casing stressed

8、Curve tolerance according to ISO 9906

Special mechanical seal

Other voltages or frequency 60Hz

Single phase motor with built-in capacitor

(according to our general sales conditions)

|

Materials Table |

||

|

NO. |

Part |

Material |

|

1 |

Pump external casing |

AISI 304 SS |

|

2 |

Delivery casing |

Cast-Cu ASTM C85500 / AISI304SS / Cast-iron |

|

3 |

Suction lantern |

Cast-Cu ASTM C85500 / AISI304SS/ Cast-iron |

|

4 |

Diffuser |

Plastic.PC / Plastic.ABC |

|

5 |

Impeller |

Plastic.POM |

|

6 |

Pump shaft |

AISI 304 SS |

|

7 |

Shaft coupling |

AISI 304 SS |

|

8 |

Wear ring |

AISI 304 SS |

|

9 |

Motor external casing |

AISI 304 SS |

|

10 |

Top cover |

① Cast-Cu ASTM C85500 ② Cast-iron ASTM NO.30 |

|

11 |

Bottom support |

AISI 304 SS |

|

12 |

Mechanical Seal |

Special seal for deep well (Graphite-Ceramic/TC) |

|

13 |

Seal lubricant oil |

Oil for food machinery and pharmaceutic use |

|

14 |

Motor shaft |

AISI 304 SS-ASTM 5140 |

|

Model |

Power |

Deliver |

||||||||||||||

|

1~220-240V |

3~380-415V |

KW |

HP |

Q(m³/h) |

0 |

0.3 |

0.6 |

0.9 |

1.2 |

1.5 |

1.8 |

2.1 |

2.4 |

2.7 |

3.0 |

3.3 |

|

Q(l/min) |

0 |

5 |

10 |

15 |

20 |

25 |

30 |

35 |

40 |

45 |

50 |

55 |

||||

|

3.5SDM2/8 |

3.5SD2/8 |

0.25 |

0.33 |

H(m) |

47 |

47 |

46 |

45 |

43 |

41 |

38 |

34 |

29 |

24 |

18 |

12 |

|

3.5SDM2/11 |

3.5SD2/11 |

0.37 |

0.5 |

65 |

64 |

63 |

62 |

59 |

56 |

52 |

46 |

40 |

33 |

25 |

16 |

|

|

3.5SDM2/14 |

3.5SD2/14 |

0.55 |

0.75 |

83 |

82 |

81 |

79 |

76 |

71 |

66 |

59 |

51 |

42 |

32 |

21 |

|

|

3.5SDM2/17 |

3.5SD2/17 |

0.75 |

1 |

100 |

99 |

98 |

95 |

92 |

87 |

80 |

72 |

62 |

51 |

39 |

25 |

|

|

3.5SDM2/21 |

3.5SD2/21 |

0.92 |

1.25 |

124 |

123 |

121 |

118 |

113 |

107 |

99 |

89 |

76 |

63 |

48 |

31 |

|

|

3.5SDM2/24 |

3.5SD2/24 |

1.1 |

1.5 |

142 |

140 |

138 |

135 |

130 |

122 |

113 |

101 |

87 |

72 |

54 |

36 |

|

|

3.5SDM2/28 |

3.5SD2/28 |

1.3 |

1.75 |

165 |

164 |

161 |

157 |

151 |

143 |

132 |

118 |

102 |

84 |

63 |

42 |

|

|

3.5SDM2/32 |

3.5SD2/32 |

1.5 |

2 |

189 |

187 |

185 |

180 |

173 |

163 |

150 |

135 |

116 |

96 |

73 |

47 |

|

|

3.5SDM2/38 |

3.5SD2/38 |

18 |

2.5 |

224 |

222 |

219 |

213 |

205 |

194 |

179 |

160 |

138 |

114 |

86 |

56 |

|

|

-- |

3.5SD2/44 |

2.2 |

3 |

260 |

257 |

254 |

247 |

238 |

224 |

207 |

186 |

160 |

132 |

100 |

65 |

|

|

-- |

3.5SD2/52 |

3 |

4 |

307 |

304 |

300 |

292 |

281 |

265 |

244 |

219 |

189 |

156 |

118 |

77 |

|

|

Model |

Power |

Deliver |

|||||||||

|

1~110V/220V |

3~220V/380V |

KW |

HP |

Q(m³/h) |

0 |

0.6 |

1.2 |

1.8 |

2.4 |

3.0 |

3.6 |

|

Q(l/min) |

0 |

10 |

20 |

30 |

40 |

50 |

60 |

||||

|

3.5SDM2/5 |

3.5SD2/5 |

0.25 |

0.33 |

H(m) |

43 |

42 |

41 |

39 |

34 |

27 |

17 |

|

3.5SDM2/7 |

3.5SD2/7 |

0.37 |

0.5 |

60 |

59 |

58 |

55 |

48 |

38 |

24 |

|

|

3.5SDM2/10 |

3.5SD2/10 |

0.55 |

0.75 |

86 |

85 |

83 |

78 |

68 |

54 |

34 |

|

|

3.5SDM2/13 |

3.5SD2/13 |

0.75 |

1 |

111 |

110 |

108 |

102 |

88 |

71 |

44 |

|

|

3.5SDM2/16 |

3.5SD2/16 |

0.92 |

1.25 |

137 |

136 |

132 |

125 |

109 |

87 |

54 |

|

|

3.5SDM2/19 |

3.5SD2/19 |

1.1 |

1.5 |

163 |

161 |

157 |

149 |

129 |

103 |

64 |

|

|

3.5SDM2/22 |

3.5SD2/22 |

1.3 |

1.75 |

188 |

187 |

182 |

172 |

150 |

120 |

74 |

|

|

3.5SDM2/25 |

3.5SD2/25 |

1.5 |

2 |

214 |

212 |

207 |

196 |

170 |

136 |

84 |

|

A borehole pump manufacturer plays an important role in water supply systems, especially in areas where surface water is...

READ MOREWater drawn from deep underground plays a key role in agriculture, industry, and residential supply. Behind this process...

READ MOREEfficient irrigation plays a key role in modern agriculture, landscaping, and water management projects. An experienced ...

READ MORE

Pressure Switch for Water Pump Pressure range : 0.5-3.5 BAR Rated Current : 4A ;...

See Details

Carbon steel flange Working temperature: -10°C~99°C (Butyl) -10°C~99°C (EPDM) 0°...

See Details

Stainless steel Working temperature: -20°C~99°C (Butyl) -20°C~99°C (EPDM) 0°C~77...

See Details

Hot And Cold Water Circulation Pump Inlet / Outlet: 1" x 1" Body length: 130mm ...

See Details

6" Size AC/DC With Water Filled Motor Permanent Magnet Brushless

See Details

Motor power : 1.5kW-5.5kW Rated voltage : 380V Ultra-large Capacity Submersible ...

See Details