4SPM2 4" Stainless Steel Impeller Overload Protection High Efficiency Borehole Submersible Pump

View All Products

en

The 4SPM2 4" Stainless Steel Impeller Overload Protection High Efficiency Borehole Submersible Pump is a reliable and efficient water pumping solution designed for borehole applications. This pump is equipped with a stainless steel impeller, overload protection, and high efficiency features.

1、The stainless steel impeller is a key feature of this pump, providing durability and resistance to corrosion. It is designed to efficiently move water, ensuring optimal performance and longevity of the pump.

2、The overload protection feature is designed to safeguard the pump from damage caused by excessive load or electrical issues. It automatically shuts off the pump when it detects an overload, preventing motor burnout and extending the lifespan of the pump.

3、The high efficiency design of the pump ensures that it operates with minimal energy consumption. This not only reduces electricity costs but also makes the pump environmentally friendly.

4、The 4SPM2 pump is specifically designed for borehole applications, allowing it to be fully submerged in water. This submersible design maximizes efficiency and minimizes noise, making it suitable for various settings including residential, commercial, or agricultural.

5、Maximum fluid temperature up to +50℃

6、Maximum sand content : 0.25%

7、Minimum well diameter : 4"

1. Electric motor with rewind capability

2. Single-phase: 110-220V/60Hz or Three-phase: 220-380V/60Hz power supply options

3. Equipped with a starter control box or digital automatic control box

4. Pumps designed with stress considerations on the casing

5. Compliant with NEMA dimensional standards for consistency

6. Curve tolerances adhere to ISO 9903 guidelines for accuracy.

Special mechanical seal

Other voltages or frequency 50Hz

Single phase motor with built-in capacitor

(according to our general sales conditions)

|

Materials Table |

||

|

NO. |

Part |

Material |

|

1 |

Pump external casing |

AISI 304 SS |

|

2 |

Delivery casing |

AISI 304 SS |

|

3 |

Suction lantern |

AISI 304 SS |

|

4 |

Diffuser |

AISI 304 SS |

|

5 |

Impeller |

AISI 304 SS |

|

6 |

Pump shaft |

AISI 304 SS |

|

7 |

Shaft coupling |

AISI 304 SS |

|

8 |

Wear ring |

Rubber |

|

9 |

Motor external casing |

AISI 304 SS |

|

10 |

Oil chamber |

Cast-Cu ASTM C85500 Cast-iron ASTM NO.30 AISI 304 SS |

|

11 |

Bottom support |

AISI 304 SS |

|

12 |

Mechanical Seal |

Special seal for deep well (Graphite-Ceramic) |

|

13 |

Seal lubricant oil |

Oil for food machinery and pharmaceutic use |

|

14 |

Motor shaft |

AISI 304 SS-ASTM 5140 |

|

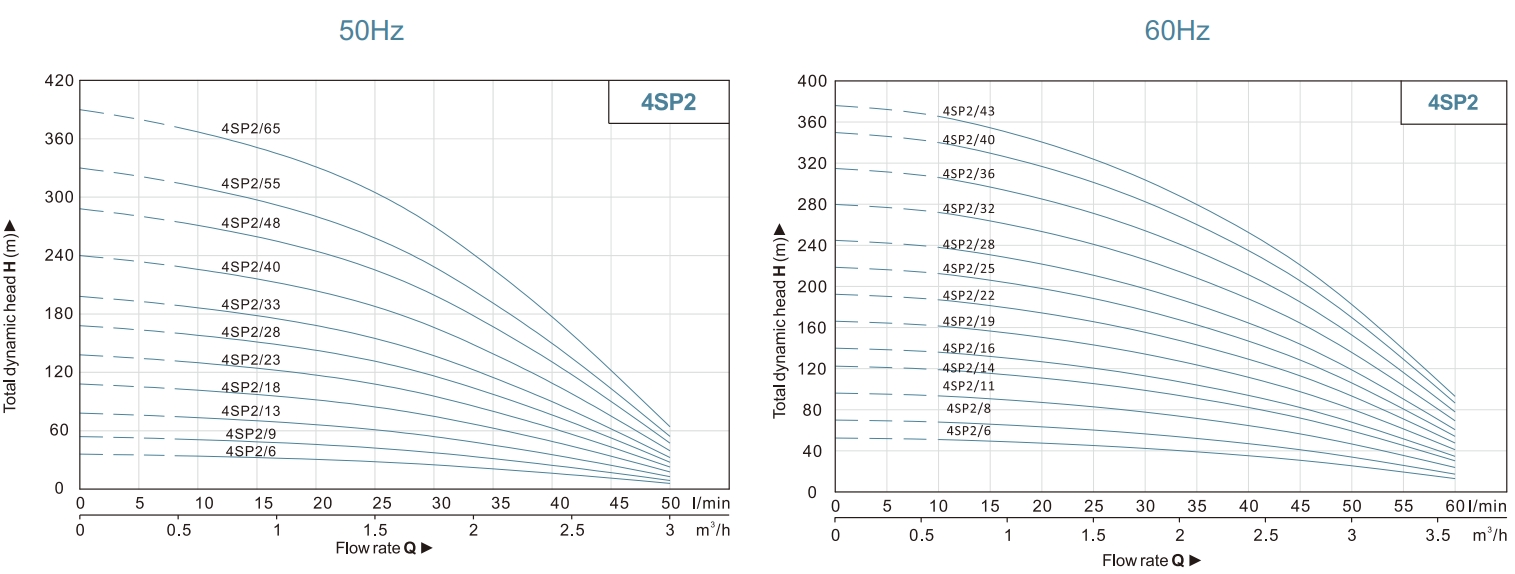

Model |

Power |

Deliver |

|||||||||||||

|

1~220V-240V |

3~380V-415V |

KW |

HP |

Q(m³/h) |

0 |

0.3 |

0.6 |

0.9 |

1.2 |

1.5 |

1.8 |

2.1 |

2.4 |

2.7 |

3.0 |

|

Q(l/min) |

0 |

5 |

10 |

15 |

20 |

25 |

30 |

35 |

40 |

45 |

50 |

||||

|

4SPM2/6 |

4SP2/6 |

0.37 |

0.5 |

H(m) |

36 |

35 |

34 |

32 |

31 |

28 |

25 |

21 |

16 |

11 |

6 |

|

4SPM2/9 |

4SP2/9 |

0.37 |

0.5 |

54 |

53 |

51 |

48 |

46 |

42 |

37 |

31 |

25 |

17 |

9 |

|

|

4SPM2/13 |

4SP2/13 |

0.55 |

0.75 |

78 |

76 |

73 |

70 |

66 |

61 |

54 |

45 |

35 |

24 |

13 |

|

|

4SPM2/18 |

4SP2/18 |

0.75 |

1 |

108 |

105 |

102 |

97 |

92 |

85 |

75 |

63 |

49 |

34 |

18 |

|

|

4SPM2/23 |

4SP2/23 |

1.1 |

1.5 |

138 |

134 |

130 |

124 |

117 |

108 |

96 |

80 |

63 |

43 |

23 |

|

|

4SPM2/28 |

4SP2/28 |

1.3 |

1.75 |

168 |

164 |

158 |

151 |

143 |

132 |

116 |

97 |

76 |

53 |

28 |

|

|

4SPM2/33 |

4SP2/33 |

1.5 |

2 |

198 |

193 |

186 |

178 |

168 |

155 |

137 |

115 |

90 |

62 |

32 |

|

|

4SPM2/40 |

4SP2/40 |

1.8 |

2.5 |

240 |

234 |

226 |

215 |

204 |

188 |

166 |

139 |

109 |

75 |

39 |

|

|

4SPM2/48 |

4SP2/48 |

2.2 |

3 |

288 |

281 |

271 |

258 |

244 |

226 |

199 |

167 |

131 |

90 |

47 |

|

|

4SPM2/55 |

4SP2/55 |

2.6 |

3.5 |

330 |

322 |

311 |

296 |

280 |

259 |

228 |

191 |

150 |

103 |

54 |

|

|

4SPM2/65 |

4SP2/65 |

3 |

4 |

390 |

380 |

367 |

350 |

331 |

306 |

270 |

226 |

177 |

122 |

64 |

|

|

Model |

Power |

Deliver |

|||||||||||||||

|

1~110V/220V |

3~220V/380V |

KW

|

HP

|

Q(m³/h) |

0 |

0.3 |

0.6 |

0.9 |

1.2 |

1.5 |

1.8 |

2.1 |

2.4 |

2.7 |

3.0 |

3.3 |

3.6 |

|

Q(l/min) |

0 |

5 |

10 |

15 |

20 |

25 |

30 |

35 |

40 |

45 |

50 |

55 |

60 |

||||

|

4SPM2/6 |

4SP2/6 |

0.37 |

0.5 |

H(m) |

52 |

52 |

51 |

49 |

47 |

45 |

42 |

38 |

35 |

30 |

25 |

18 |

12 |

|

4SPM2/8 |

4SP2/8 |

0.55 |

0.75 |

70 |

69 |

68 |

66 |

63 |

60 |

56 |

52 |

47 |

42 |

34 |

26 |

17 |

|

|

4SPM2/11 |

4SP2/11 |

0.75 |

1 |

96 |

95 |

93 |

90 |

87 |

83 |

77 |

71 |

65 |

57 |

47 |

35 |

24 |

|

|

4SPM2/14 |

4SP2/14 |

0.92 |

1.25 |

122 |

121 |

119 |

115 |

111 |

106 |

98 |

91 |

83 |

73 |

60 |

45 |

30 |

|

|

4SPM2/16 |

4SP2/16 |

1.1 |

1.5 |

140 |

138 |

136 |

131 |

127 |

121 |

112 |

104 |

95 |

83 |

69 |

51 |

34 |

|

|

4SPM2/19 |

4SP2/19 |

1.3 |

1.75 |

166 |

164 |

161 |

156 |

150 |

143 |

133 |

123 |

112 |

99 |

81 |

61 |

41 |

|

|

4SPM2/22 |

4SP2/22 |

1.5 |

2 |

193 |

90 |

187 |

180 |

174 |

166 |

154 |

143 |

130 |

114 |

94 |

70 |

47 |

|

|

4SPM2/25 |

4SP2/25 |

1.8 |

2.5 |

219 |

216 |

212 |

205 |

198 |

189 |

175 |

162 |

148 |

130 |

107 |

80 |

54 |

|

|

4SPM2/28 |

4SP2/28 |

2.2 |

3 |

245 |

242 |

238 |

230 |

222 |

211 |

196 |

182 |

166 |

146 |

120 |

90 |

60 |

|

|

- |

4SP2/32 |

2.6 |

3.5 |

280 |

276 |

272 |

262 |

253 |

241 |

224 |

208 |

189 |

166 |

137 |

102 |

69 |

|

|

- |

4SP2/36 |

3 |

4 |

315 |

311 |

306 |

295 |

285 |

271 |

252 |

234 |

213 |

187 |

154 |

115 |

78 |

|

|

- |

4SP2/40 |

3.7 |

5 |

350 |

345 |

340 |

328 |

316 |

301 |

280 |

260 |

236 |

208 |

171 |

128 |

86 |

|

|

- |

4SP2/43 |

4 |

5.5 |

376 |

371 |

366 |

352 |

340 |

324 |

301 |

280 |

254 |

223 |

184 |

137 |

93 |

|

A submersible pump factory is responsible for producing pumps that operate fully underwater while maintaining stable per...

READ MOREA borehole pump manufacturer plays an important role in water supply systems, especially in areas where surface water is...

READ MOREWater drawn from deep underground plays a key role in agriculture, industry, and residential supply. Behind this process...

READ MORE

Dustproof Design Stable ChassisPlain Washer Multistage DesignHigh-Quality Constr...

See Details

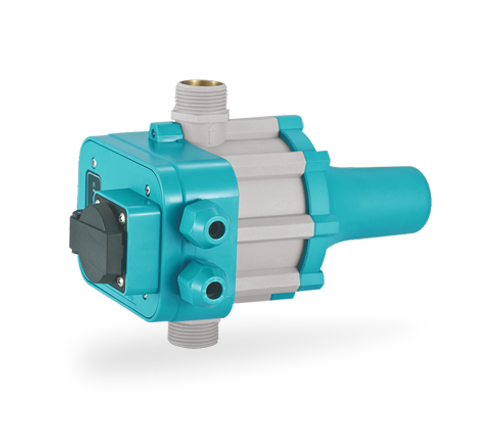

Zinc Alloy Bottom Antifatiguefor water pumpsPressure range : 15-100psiPressure s...

See Details

Starting pressure : 1.2bar - 3.0barMax. Rated Current : 10AMax. Allowable Press...

See Details

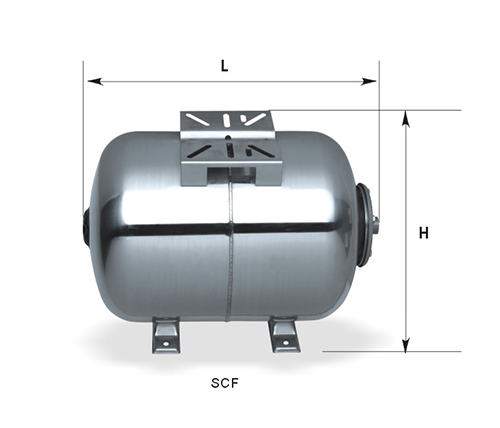

Stainless steel Working temperature: -20°C~99°C (Butyl) -20°C~99°C (EPDM) 0°C~77...

See Details

6" Size AC/DC With Water Filled Motor Permanent Magnet Brushless

See Details

Rated Voltage : 380V Motor Power : 1.5kW-5.5kW Water Level Sensor Intelligent Su...

See Details