4SPM3 4" Low Energy Consumption Stainless Steel Motor Borehole Deep Well Pump

View All Products

en

4" Low Energy Consumption Stainless Steel Motor Borehole Deep Well Pump is a reliable and efficient solution for all your borehole submersible pump needs. This top-of-the-line pump is designed to deliver exceptional performance, ensuring a constant and steady water supply for various applications. With its cutting-edge technology and robust construction, this pump is built to withstand the most demanding conditions, making it the ideal choice for deep well installations.

1、Crafted with precision and engineered for excellence, this deep well pump boasts a low energy consumption stainless steel motor. This motor not only ensures superior durability but also guarantees efficient power consumption, resulting in significant energy savings.

2、The motor is also equipped with a heating mass capacity, ensuring optimal performance even in extreme temperatures. 3、Its compact and ergonomic design ensures hassle-free setup, while its durable construction guarantees long-lasting performance. With its user-friendly interface, operating this pump is a breeze, allowing you to focus on your tasks without any unnecessary complications..

4、Equipped with advanced features, this submersible pump offers unparalleled performance. Its high-pressure capabilities allow it to deliver water at a consistent and powerful rate, making it suitable for a wide range of applications, including irrigation, domestic water supply, and industrial use.

5、Maximum fluid temperature up to +50℃

6、Maximum sand content : 0.25%

7、Minimum well diameter : 4"

1. Electric motor with rewindable feature

2. Single-phase options: 110/220V/60Hz or Three-phase options: 220/380V/60Hz

3. Equipped with a starter control box or digital automatic control box

4. Pumps are designed with casing stress analysis

5. Adheres to NEMA dimensional standards

6. Curve tolerances comply with ISO 9903 guidelines

Special mechanical seal

Other voltages or frequency 60Hz

Single phase motor with built-in capacitor

(according to our general sales conditions)

|

Materials Table |

||

|

NO. |

Part |

Material |

|

1 |

Pump external casing |

AISI 304 SS |

|

2 |

Delivery casing |

AISI 304 SS |

|

3 |

Suction lantern |

AISI 304 SS |

|

4 |

Diffuser |

AISI 304 SS |

|

5 |

Impeller |

AISI 304 SS |

|

6 |

Pump shaft |

AISI 304 SS |

|

7 |

Shaft coupling |

AISI 304 SS |

|

8 |

Wear ring |

Rubber |

|

9 |

Motor external casing |

AISI 304 SS |

|

10 |

Oil chamber |

Cast-Cu ASTM C85500 Cast-iron ASTM NO.30 AISI 304 SS |

|

11 |

Bottom support |

AISI 304 SS |

|

12 |

Mechanical Seal |

Special seal for deep well (Graphite-Ceramic) |

|

13 |

Seal lubricant oil |

Oil for food machinery and pharmaceutic use |

|

14 |

Motor shaft |

AISI 304 SS-ASTM 5140 |

|

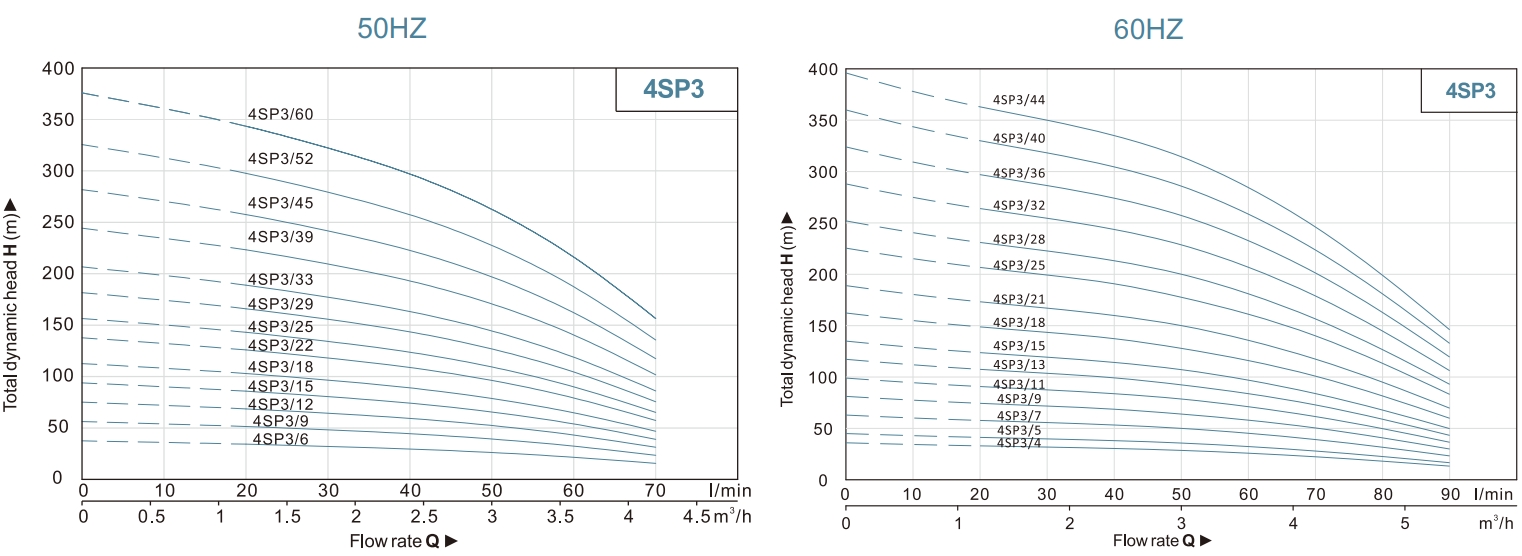

Model |

Power |

Deliver |

||||||||||

|

1~220-240V |

3~380-415V |

KW |

HP |

Q(m³/h) |

0 |

0.6 |

1.2 |

1.8 |

2.4 |

3.0 |

3.6 |

4.2 |

|

Q(l/min) |

0 |

10 |

20 |

30 |

40 |

50 |

60 |

70 |

||||

|

4SPM3/6 |

4SP3/6 |

0.37 |

0.5 |

H(m) |

37 |

36 |

34 |

32 |

29 |

26 |

21 |

15 |

|

4SPM3/9 |

4SP3/9 |

0.55 |

0.75 |

56 |

54 |

51 |

48 |

44 |

39 |

32 |

23 |

|

|

4SPM3/12 |

4SP3/12 |

0.75 |

1 |

74 |

71 |

68 |

64 |

59 |

52 |

43 |

31 |

|

|

4SPM3/15 |

4SP3/15 |

0.92 |

1.25 |

93 |

89 |

85 |

80 |

73 |

65 |

53 |

39 |

|

|

4SPM3/18 |

4SP3/18 |

1.1 |

1.5 |

112 |

107 |

102 |

96 |

88 |

78 |

64 |

46 |

|

|

4SPM3/22 |

4SP3/22 |

1.3 |

1.75 |

136 |

131 |

125 |

117 |

108 |

95 |

78 |

57 |

|

|

4SPM3/25 |

4SP3/25 |

1.5 |

2 |

155 |

149 |

142 |

133 |

122 |

108 |

89 |

65 |

|

|

4SPM3/29 |

4SP3/29 |

1.8 |

2.5 |

180 |

173 |

164 |

154 |

142 |

126 |

103 |

75 |

|

|

4SPM3/33 |

4SP3/33 |

2.2 |

3 |

205 |

196 |

187 |

175 |

162 |

143 |

118 |

85 |

|

|

4SPM3/39 |

4SP3/39 |

2.6 |

3.5 |

242 |

232 |

221 |

207 |

191 |

169 |

139 |

101 |

|

|

4SPM3/45 |

4SP3/45 |

3 |

4 |

279 |

268 |

255 |

239 |

220 |

195 |

160 |

116 |

|

|

- |

4SP3/52 |

3.7 |

5 |

322 |

309 |

295 |

276 |

255 |

225 |

185 |

134 |

|

|

- |

4SP3/60 |

4 |

5.5 |

372 |

357 |

340 |

319 |

294 |

260 |

214 |

155 |

|

|

Model |

Power |

Deliver |

||||||||||||

|

1~110/220V |

3~220/380V |

KW |

HP |

Q(m³/h) |

0 |

0.6 |

1.2 |

1.8 |

2.4 |

3.0 |

3.6 |

4.2 |

4.8 |

5.4 |

|

Q(l/min) |

0 |

10 |

20 |

30 |

40 |

50 |

60 |

70 |

80 |

90 |

||||

|

4SPM3/4 |

4SP3/4 |

0.37 |

0.5 |

H(m) |

37 |

35 |

33 |

32 |

30 |

29 |

26 |

23 |

18 |

13 |

|

4SPM3/5 |

4SP3/5 |

0.55 |

0.75 |

46 |

44 |

42 |

41 |

39 |

36 |

33 |

29 |

23 |

17 |

|

|

4SPM3/7 |

4SP3/7 |

0.75 |

1 |

64 |

61 |

58 |

56 |

53 |

50 |

45 |

39 |

31 |

23 |

|

|

4SPM3/9 |

4SP3/9 |

0.92 |

1.25 |

81 |

77 |

74 |

72 |

69 |

64 |

58 |

50 |

41 |

30 |

|

|

4SPM3/11 |

4SP3/11 |

1.1 |

1.5 |

100 |

95 |

91 |

88 |

84 |

79 |

71 |

62 |

50 |

37 |

|

|

4SPM3/13 |

4SP3/13 |

1.3 |

1.75 |

117 |

112 |

107 |

103 |

99 |

92 |

84 |

73 |

59 |

43 |

|

|

4SPM3/15 |

4SP3/15 |

1.5 |

2 |

135 |

129 |

124 |

119 |

114 |

107 |

96 |

84 |

68 |

50 |

|

|

4SPM3/18 |

4SP3/18 |

1.8 |

2.5 |

162 |

155 |

149 |

143 |

137 |

128 |

116 |

101 |

81 |

60 |

|

|

4SPM3/21 |

4SP3/21 |

2.2 |

3 |

189 |

180 |

173 |

167 |

160 |

150 |

135 |

117 |

95 |

70 |

|

|

- |

4SP3/25 |

2.6 |

3.5 |

225 |

215 |

206 |

199 |

190 |

177 |

161 |

140 |

113 |

83 |

|

|

- |

4SP3/28 |

3 |

4 |

252 |

241 |

231 |

223 |

213 |

200 |

180 |

157 |

127 |

93 |

|

|

- |

4SP3/32 |

3.7 |

5 |

288 |

275 |

264 |

255 |

244 |

229 |

206 |

179 |

145 |

106 |

|

|

- |

4SP3/36 |

4 |

5.5 |

324 |

309 |

297 |

286 |

274 |

257 |

232 |

201 |

163 |

119 |

|

|

- |

4SP3/40 |

5 |

7 |

360 |

344 |

330 |

318 |

305 |

286 |

257 |

224 |

181 |

133 |

|

|

- |

4SP3/44 |

5.5 |

7.5 |

396 |

378 |

363 |

350 |

335 |

314 |

283 |

246 |

199 |

146 |

|

A submersible pump factory is responsible for producing pumps that operate fully underwater while maintaining stable per...

READ MOREA borehole pump manufacturer plays an important role in water supply systems, especially in areas where surface water is...

READ MOREWater drawn from deep underground plays a key role in agriculture, industry, and residential supply. Behind this process...

READ MORE

Carbon steel flange Working temperature: -10°C~99°C (Butyl) -10°C~99°C (EPDM) 0°...

See Details

Carbon steel flange Working temperature: -10°C~99°C (Butyl) -10°C~99°C (EPDM)

See Details

Replaceable membrane pressure tanksCarbon steel flangeWorking temperature : -10°...

See Details

Low Noise High Quality Extensively used High efficient running

See Details

Stainless steel materialsHigh flow rate and high-lift Self-priming JET Pump

See Details

Rated voltage : 380V Motor power : 1.5kW-5.5kW Intelligent Drainage and Slurry P...

See Details