6SP30 6" Low Energy Consumption Sand Resistance Stainless Steel Impeller Borehole Submersible Pump for Urban Sewage Treatment

View All Products

en

Designed specifically for deep well applications, this pump is perfect for various industries, including urban sewage treatment facilities. With its exceptional performance and durable construction, it is the ideal choice for professionals seeking a high-quality water pump.

1、One of the standout features of this pump is its low energy consumption. By utilizing advanced technology, it minimizes energy usage without compromising on performance. This not only helps you save on electricity costs but also contributes to a more sustainable and eco-friendly operation.

2、The Submersible Water Pump for Deep Wells is equipped with a stainless steel impeller, which enhances its durability and resistance to wear and tear. This impeller is specifically designed to withstand the abrasive nature of sand and other particles commonly found in deep well water sources.

3、 Its powerful motor ensures a reliable and efficient operation, allowing you to effortlessly extract water from deep underground sources. Whether you require water for irrigation, industrial processes, or urban sewage treatment, this pump is designed to meet your demands.

4、Maximum fluid temperature up to +50℃

5、Maximum sand content : 0.25%

6、Minimum well diameter : 6"

Rewindable Electric Motor

Single-phase: 220-240V/50Hz

Three-phase: 380-415V/50Hz

Starting Methods:

① Direct-on-line (1 cable)

② Star-delta (2 cables)

Equipped with a start control box or digital auto-control box

Compliant with NEMA dimension standards

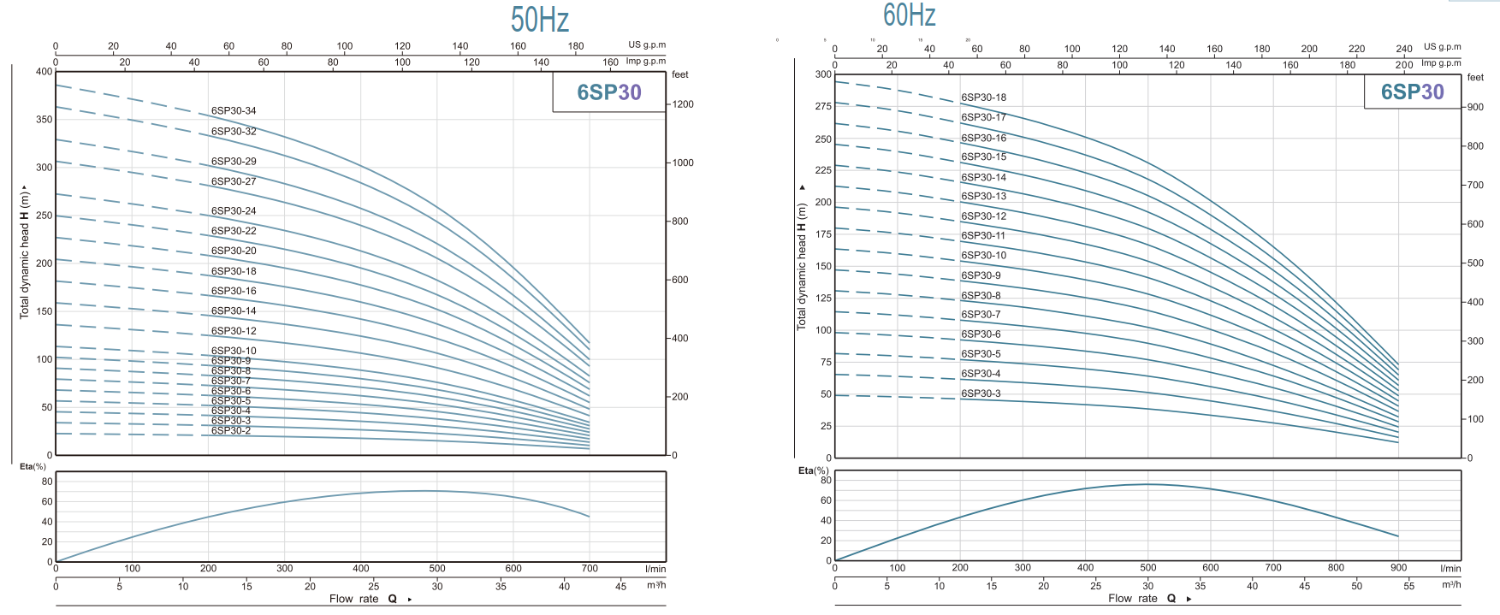

Curve tolerance in accordance with ISO 9906

Special mechanical seal

Other voltages or frequency 60Hz

(according to our general sales conditions)

CE Certificate :

Product Line :

|

Components |

Material |

|

Delivery casing |

AISI 304 SS |

|

Suction lantern |

AISI 304 SS |

|

Diffuser |

AISI 304 SS |

|

Impeller |

AISI 304 SS |

|

Shaft |

AISI 304 SS |

|

Shaft coupling |

AISI 304 SS |

|

Wear ring |

Rubber |

|

Motor external casing |

AISI 304 SS |

|

Oil chamber |

Cast-iron ASTM NO.30 |

|

Bottom support |

Cast-iron ASTM NO.30 |

|

Seal |

NBR Graphite-SIC/TC |

|

Shaft |

AISI 304 SS-ASTM 5140 |

|

Model |

Power |

Deliver |

||||||||||

|

1~220V/240V |

3~380V/415V |

KW |

HP |

Q(m³/h) |

0 |

6 |

12 |

18 |

24 |

30 |

36 |

42 |

|

Q(l/min) |

0 |

100 |

200 |

300 |

400 |

500 |

600 |

700 |

||||

|

6SPM30/2 |

6SP30/2 |

2.2 |

3 |

H(m) |

23 |

22 |

21 |

19 |

18 |

15 |

11 |

7 |

|

6SPM30/3 |

6SP30/3 |

3 |

4 |

34 |

33 |

31 |

29 |

27 |

23 |

17 |

11 |

|

|

6SPM30/4 |

6SP30/4 |

4 |

5.5 |

46 |

44 |

42 |

39 |

36 |

31 |

23 |

14 |

|

|

6SPM30/5 |

6SP30/5 |

5.5 |

7.5 |

57 |

56 |

52 |

48 |

44 |

38 |

29 |

18 |

|

|

6SPM30/6 |

6SP30/6 |

5.5 |

10 |

68 |

67 |

63 |

58 |

53 |

46 |

34 |

21 |

|

|

- |

6SP30/7 |

7.5 |

12.5 |

80 |

78 |

73 |

68 |

62 |

54 |

40 |

25 |

|

|

- |

6SP30/8 |

7.5 |

12.5 |

91 |

89 |

84 |

77 |

71 |

61 |

46 |

28 |

|

|

- |

6SP30/9 |

9.2 |

15 |

102 |

100 |

94 |

87 |

80 |

69 |

52 |

32 |

|

|

- |

6SP30/10 |

9.2 |

15 |

114 |

111 |

105 |

96 |

89 |

76 |

57 |

35 |

|

|

- |

6SP30/12 |

11 |

17.5 |

137 |

133 |

126 |

116 |

107 |

92 |

69 |

42 |

|

|

- |

6SP30/14 |

13 |

20 |

159 |

156 |

147 |

135 |

124 |

107 |

80 |

49 |

|

|

- |

6SP30/16 |

15 |

20 |

182 |

178 |

168 |

154 |

142 |

122 |

92 |

56 |

|

|

- |

6SP30/18 |

18.5 |

25 |

205 |

200 |

189 |

174 |

160 |

138 |

103 |

64 |

|

|

- |

6SP30/20 |

18.5 |

25 |

228 |

222 |

210 |

193 |

178 |

153 |

115 |

71 |

|

|

- |

6SP30/22 |

22 |

30 |

250 |

245 |

231 |

212 |

195 |

168 |

126 |

78 |

|

|

- |

6SP30/24 |

22 |

30 |

273 |

267 |

252 |

232 |

213 |

184 |

138 |

85 |

|

|

- |

6SP30/27 |

26 |

35 |

307 |

300 |

284 |

260 |

240 |

206 |

155 |

95 |

|

|

- |

6SP30/29 |

26 |

35 |

330 |

322 |

305 |

280 |

258 |

222 |

166 |

102 |

|

|

- |

6SP30/32 |

30 |

40 |

364 |

356 |

336 |

309 |

284 |

245 |

184 |

113 |

|

|

- |

6SP30/34 |

30 |

40 |

387 |

378 |

357 |

328 |

302 |

260 |

195 |

120 |

|

|

Model |

Power |

Deliver |

||||||||||

|

3~220V/380V |

KW |

HP |

Q(m³/h) |

0 |

5 |

10 |

15 |

20 |

25 |

30 |

35 |

40 |

|

Q(l/min) |

0 |

83 |

167 |

250 |

333 |

417 |

500 |

583 |

667 |

|||

|

6SP30/3 |

4 |

5.5 |

H(m) |

56 |

55 |

54 |

52 |

49 |

43 |

34 |

23 |

8 |

|

6SP30/4 |

5.5 |

7.5 |

86 |

85 |

83 |

80 |

75 |

66 |

53 |

35 |

12 |

|

|

6SP30/5 |

7.5 |

10 |

108 |

106 |

104 |

100 |

94 |

82 |

66 |

44 |

16 |

|

|

6SP30/6 |

9.2 |

12.5 |

129 |

127 |

125 |

120 |

112 |

98 |

79 |

53 |

19 |

|

|

6SP30/7 |

11 |

15 |

151 |

148 |

146 |

140 |

131 |

115 |

92 |

62 |

22 |

|

|

6SP30/8 |

13 |

17.5 |

172 |

170 |

166 |

160 |

150 |

131 |

106 |

70 |

25 |

|

|

6SP30/10 |

15 |

20 |

215 |

212 |

208 |

200 |

187 |

164 |

132 |

88 |

31 |

|

A submersible pump factory is responsible for producing pumps that operate fully underwater while maintaining stable per...

READ MOREA borehole pump manufacturer plays an important role in water supply systems, especially in areas where surface water is...

READ MOREWater drawn from deep underground plays a key role in agriculture, industry, and residential supply. Behind this process...

READ MORE

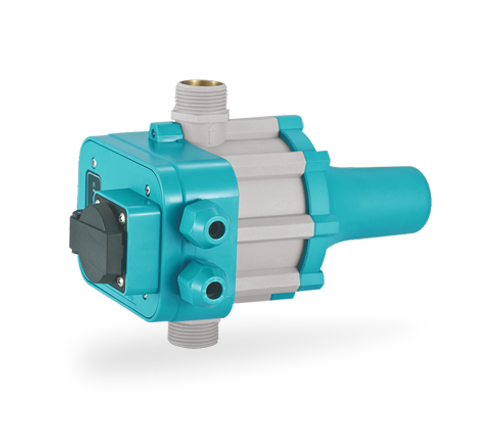

Starting pressure : 1.2bar - 3.0barMax. Rated Current : 10AMax. Allowable Press...

See Details

Carbon steel flange Working temperature: -10°C~99°C (Butyl) -10°C~99°C (EPDM) 0°...

See Detailsaseriesnoisereductiondesignacid-baseverticalsurfacepump-1.jpg)

Identify noise sourcesAnalyze the operating conditionsUse noise reduction techni...

See Details

Energy Saving Hot And Cold Water Circulation Pump Inlet / Outlet: 1.5" x 1.5" Bo...

See Details

Stainless steel materialsHigh flow rate and high-lift Self-priming JET Pump

See Details

Rated voltage : 380V Motor power : 1.5kW-5.5kW Intelligent Drainage and Slurry P...

See Details