6SP46 6" Stainless Steel Shaft 135 Degree Thermal Protector Borehole Submersible Pump

View All Products

en

The 6SP46 6" Stainless Steel Shaft 135 Degree Thermal Protector Borehole Submersible Pump is a high-quality water pumping solution designed for borehole applications. This pump features a stainless steel shaft, a 135 degree thermal protector, and is manufactured in China.

1、The stainless steel shaft of the pump provides durability and resistance to corrosion, ensuring a long lifespan and reliable performance even in challenging water conditions.

2、The 135-degree thermal protector is a safety feature that helps prevent motor overheating. It automatically shuts off the pump when the temperature reaches a certain threshold, protecting the motor from damage and ensuring safe operation.

3、Manufactured in China, this pump meets high-quality standards and is built to deliver reliable and efficient performance. Chinese manufacturing is known for its expertise in producing durable and cost-effective products.

4、The 6SP46 pump is specifically designed for borehole applications, allowing it to be fully submerged in water. This submersible design maximizes efficiency and minimizes noise, making it suitable for various settings including residential, commercial, or agricultural.

5、Maximum fluid temperature up to +50℃

6、Maximum sand content : 0.25%

7、Minimum well diameter : 6"

Rewindable Electric Motor

Single-phase: 220-240V/50Hz

Three-phase: 380-415V/50Hz

Available with direct start (1 cable) or star-delta start (2 cables)

Comes equipped with a start control box or digital auto-control box

Conforms to NEMA dimension standards

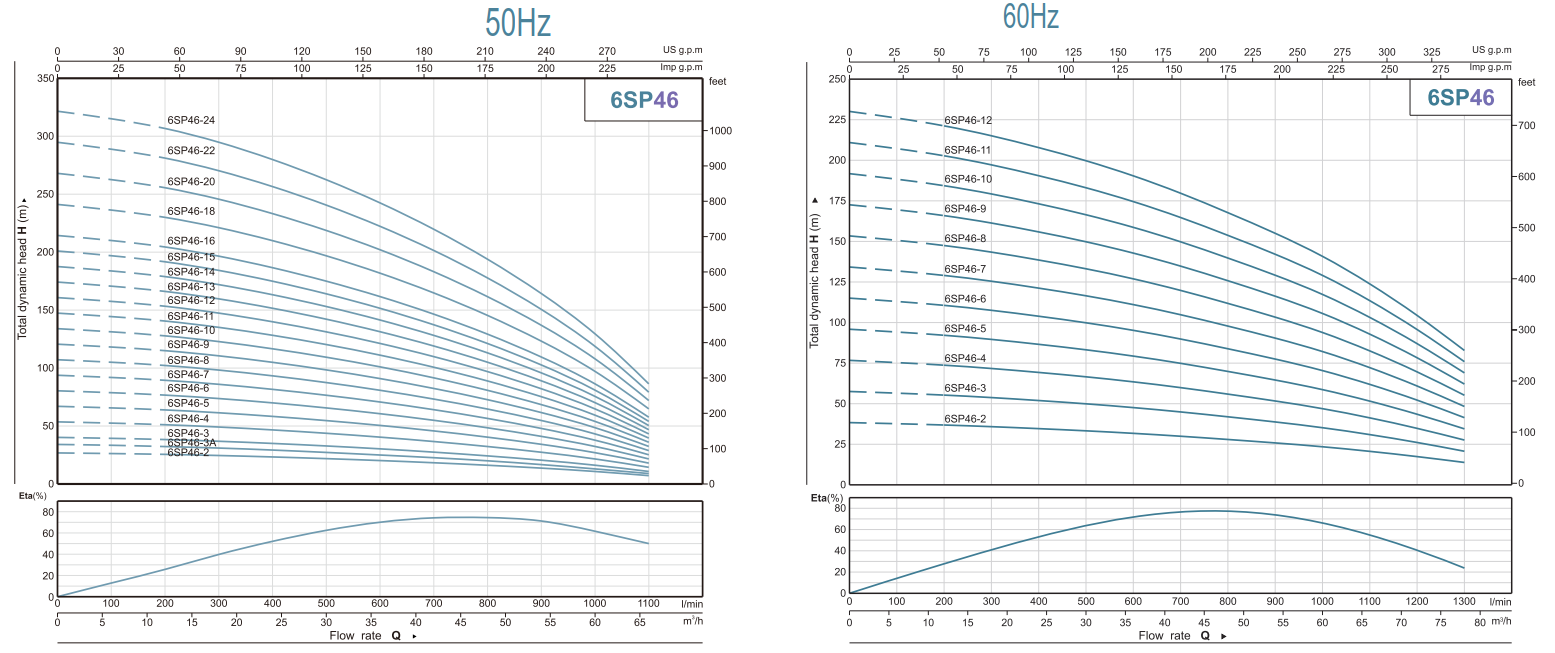

Curve tolerance in accordance with ISO 9906

Special mechanical seal

Other voltages or frequency 60Hz

(according to our general sales conditions)

CE Certificate :

Product Line :

|

Components |

Material |

|

Delivery casing |

AISI 304 SS |

|

Suction lantern |

AISI 304 SS |

|

Diffuser |

AISI 304 SS |

|

Impeller |

AISI 304 SS |

|

Shaft |

AISI 304 SS |

|

Shaft coupling |

AISI 304 SS |

|

Wear ring |

Rubber |

|

Motor external casing |

AISI 304 SS |

|

Oil chamber |

Cast-iron ASTM NO.30 |

|

Bottom support |

Cast-iron ASTM NO.30 |

|

Seal |

NBR Graphite-SIC/TC |

|

Shaft |

AISI 304 SS-ASTM 5140 |

|

Model |

Power |

Deliver |

||||||||||||||

|

1~220V-240V |

3~380V-415V |

KW |

HP |

Q(m³/h) |

0 |

6 |

12 |

18 |

24 |

30 |

36 |

42 |

48 |

54 |

60 |

66 |

|

Q(l/min) |

0 |

100 |

200 |

300 |

400 |

500 |

600 |

700 |

800 |

900 |

1000 |

1100 |

||||

|

6SPM46/2 |

6SP46/2 |

3 |

4 |

H(m) |

27 |

26 |

26 |

25 |

23 |

22 |

20 |

18 |

16 |

14 |

11 |

7 |

|

6SPM46/3A |

6SP46/3A |

4 |

5.5 |

35 |

34 |

32 |

31 |

29 |

26 |

25 |

22 |

20 |

16 |

13 |

9 |

|

|

6SPM46/3 |

6SP46/3 |

5.5 |

7.5 |

40 |

39 |

38 |

37 |

35 |

32 |

30 |

27 |

24 |

2 |

16 |

11 |

|

|

- |

6SP46/4 |

7.5 |

10 |

54 |

52 |

51 |

49 |

46 |

43 |

40 |

36 |

32 |

28 |

22 |

14 |

|

|

- |

6SP46/5 |

7.5 |

10 |

67 |

65 |

64 |

61 |

58 |

54 |

50 |

45 |

40 |

34 |

2 |

18 |

|

|

- |

6SP46/6 |

9.2 |

12.5 |

80 |

79 |

77 |

74 |

70 |

65 |

60 |

55 |

49 |

41 |

32 |

22 |

|

|

- |

6SP46/7 |

11 |

15 |

94 |

92 |

90 |

86 |

81 |

76 |

70 |

64 |

57 |

48 |

38 |

25 |

|

|

- |

6SP46/8 |

13 |

17.5 |

107 |

105 |

102 |

98 |

93 |

86 |

80 |

73 |

65 |

55 |

43 |

29 |

|

|

- |

6SP46/9 |

15 |

20 |

121 |

118 |

115 |

111 |

104 |

97 |

90 |

82 |

73 |

62 |

49 |

32 |

|

|

- |

6SP46/10 |

15 |

20 |

134 |

131 |

128 |

123 |

116 |

108 |

100 |

91 |

81 |

69 |

54 |

36 |

|

|

- |

6SP46/11 |

18.5 |

25 |

147 |

144 |

141 |

135 |

128 |

119 |

110 |

100 |

89 |

76 |

59 |

40 |

|

|

- |

6SP46/12 |

18.5 |

25 |

161 |

157 |

154 |

148 |

139 |

130 |

120 |

109 |

97 |

83 |

65 |

43 |

|

|

- |

6SP46/13 |

22 |

30 |

174 |

170 |

166 |

160 |

151 |

140 |

130 |

118 |

105 |

90 |

70 |

47 |

|

|

- |

6SP46/14 |

22 |

30 |

188 |

183 |

179 |

172 |

162 |

151 |

140 |

127 |

113 |

97 |

76 |

50 |

|

|

- |

6SP46/15 |

26 |

35 |

201 |

196 |

192 |

184 |

174 |

162 |

150 |

136 |

121 |

104 |

81 |

54 |

|

|

- |

6SP46/16 |

26 |

35 |

214 |

210 |

205 |

197 |

186 |

173 |

160 |

146 |

130 |

110 |

86 |

58 |

|

|

- |

6SP46/18 |

30 |

40 |

241 |

236 |

230 |

221 |

209 |

194 |

180 |

164 |

146 |

124 |

97 |

65 |

|

|

- |

6SP46/20 |

30 |

40 |

268 |

262 |

256 |

246 |

232 |

216 |

200 |

182 |

162 |

138 |

108 |

72 |

|

|

- |

6SP46/22 |

37 |

50 |

295 |

288 |

281 |

270 |

255 |

237 |

220 |

200 |

178 |

152 |

119 |

79 |

|

|

- |

6SP46/24 |

37 |

50 |

322 |

314 |

307 |

295 |

278 |

259 |

240 |

218 |

194 |

166 |

130 |

86 |

|

|

Model |

Power |

Deliver |

|||||||||||||||

|

3~220V/380V |

KW |

HP |

Q(m³/h) |

0 |

0 |

12 |

18 |

24 |

30 |

36 |

42 |

48 |

54 |

60 |

66 |

72 |

78 |

|

Q(l/min) |

0 |

100 |

200 |

300 |

400 |

500 |

600 |

700 |

800 |

900 |

1000 |

1100 |

1200 |

1300 |

|||

|

6SP46/2 |

5.5 |

75 |

H(m) |

39 |

38 |

37 |

36 |

35 |

33 |

31 |

29 |

28 |

26 |

23 |

21 |

17 |

13 |

|

6SP46/3 |

7.5 |

10 |

58 |

56 |

56 |

54 |

52 |

50 |

47 |

44 |

42 |

39 |

35 |

31 |

25 |

20 |

|

|

6SP46/4 |

9.2 |

12.5 |

77 |

75 |

74 |

72 |

69 |

66 |

62 |

59 |

56 |

52 |

47 |

41 |

34 |

27 |

|

|

6SP46/5 |

13 |

17.5 |

96 |

94 |

93 |

90 |

86 |

83 |

78 |

74 |

70 |

65 |

59 |

52 |

42 |

34 |

|

|

6SP46/6 |

15 |

20 |

116 |

113 |

111 |

108 |

104 |

99 |

93 |

88 |

83 |

77 |

82 |

62 |

51 |

40 |

|

|

6SP46/7 |

18.5 |

25 |

135 |

131 |

130 |

126 |

121 |

116 |

109 |

103 |

97 |

90 |

94 |

72 |

59 |

47 |

|

|

6SP46/8 |

22 |

30 |

154 |

150 |

148 |

144 |

138 |

132 |

125 |

118 |

111 |

103 |

106 |

83 |

68 |

54 |

|

|

6SP46/9 |

22 |

30 |

173 |

169 |

167 |

162 |

155 |

149 |

140 |

133 |

125 |

116 |

117 |

93 |

76 |

61 |

|

|

6SP46/10 |

26 |

35 |

193 |

188 |

185 |

180 |

173 |

165 |

156 |

148 |

139 |

129 |

129 |

103 |

85 |

69 |

|

|

6SP46/11 |

26 |

35 |

212 |

206 |

204 |

198 |

190 |

182 |

171 |

162 |

153 |

142 |

141 |

114 |

93 |

74 |

|

|

6SP46/12 |

30 |

40 |

231 |

225 |

222 |

216 |

207 |

198 |

187 |

177 |

167 |

155 |

35 |

124 |

102 |

81 |

|

A submersible pump factory is responsible for producing pumps that operate fully underwater while maintaining stable per...

READ MOREA borehole pump manufacturer plays an important role in water supply systems, especially in areas where surface water is...

READ MOREWater drawn from deep underground plays a key role in agriculture, industry, and residential supply. Behind this process...

READ MORE

Dustproof Design Stable ChassisPlain Washer Multistage DesignHigh-Quality Constr...

See Details

Zinc Alloy Bottom Antifatiguefor water pumpsPressure range : 15-100psiPressure s...

See Details

Starting pressure : 1.2bar - 2.2bar Max. Rated Current : 30A Max. Working Press...

See Details

Fixed diaphram membrane, carbon steel tank Pre-charge pressure of 1.5bar Max. wo...

See Details

Energy Efficiency Hot And Cold Water Circulation Pump Inlet / Outlet : 2" x 2" ...

See Details

Motor power : 1.5kW-5.5kW Rated voltage : 380V Ultra-large Capacity Submersible ...

See Details