6SP60 6" Automatically Sliencing Wear-resistant Large Flow Borehole Submersible Pump

View All Products

en

The 6SP60 6" Automatically Silencing Wear-resistant Large Flow Borehole Submersible Pump is a high-quality and efficient water pumping solution designed for borehole applications. This pump is equipped with automatic silencing, wear-resistant features, and is capable of delivering a large flow of water.

1、The automatic silencing feature of the pump helps reduce noise during operation, making it suitable for residential or noise-sensitive environments. This feature ensures a quiet and peaceful pumping experience.

2、The wear-resistant design of the pump enhances its durability and longevity. It is built to withstand the abrasive effects of water and other particles commonly found in boreholes, ensuring reliable performance over an extended period.

3、The 6SP60 pump is capable of delivering a large flow of water, making it suitable for applications where a high volume of water is required. This makes it ideal for agricultural irrigation, industrial processes, or other applications that demand a significant water flow.

4、The borehole submersible design allows the pump to be fully submerged in water, maximizing efficiency and minimizing noise. It eliminates the need for priming and reduces the risk of cavitation, ensuring smooth and efficient operation.

5、Maximum fluid temperature up to +50℃

6、Maximum sand content : 0.25%

7、Minimum well diameter : 6"

Rewindable Electric Motor

Single-Phase: 220-240V/50Hz

Three-Phase: 380-415V/50Hz

①Direct Start (1 cable)

②Star-Delta Start (2 cables)

Equipped with a Start Control Box or Digital Auto-Control Box

Conforms to NEMA Dimension Standards

Curve Tolerance in Accordance with ISO 9906

Special mechanical seal

Other voltages or frequency 60Hz

(according to our general sales conditions)

CE Certificate :

Product Line :

|

Components |

Material |

|

Delivery casing |

AISI 304 SS |

|

Suction lantern |

AISI 304 SS |

|

Diffuser |

AISI 304 SS |

|

Impeller |

AISI 304 SS |

|

Shaft |

AISI 304 SS |

|

Shaft coupling |

AISI 304 SS |

|

Wear ring |

Rubber |

|

Motor external casing |

AISI 304 SS |

|

Oil chamber |

Cast-iron ASTM NO.30 |

|

Bottom support |

Cast-iron ASTM NO.30 |

|

Seal |

NBR Graphite-SIC/TC |

|

Shaft |

AISI 304 SS-ASTM 5140 |

|

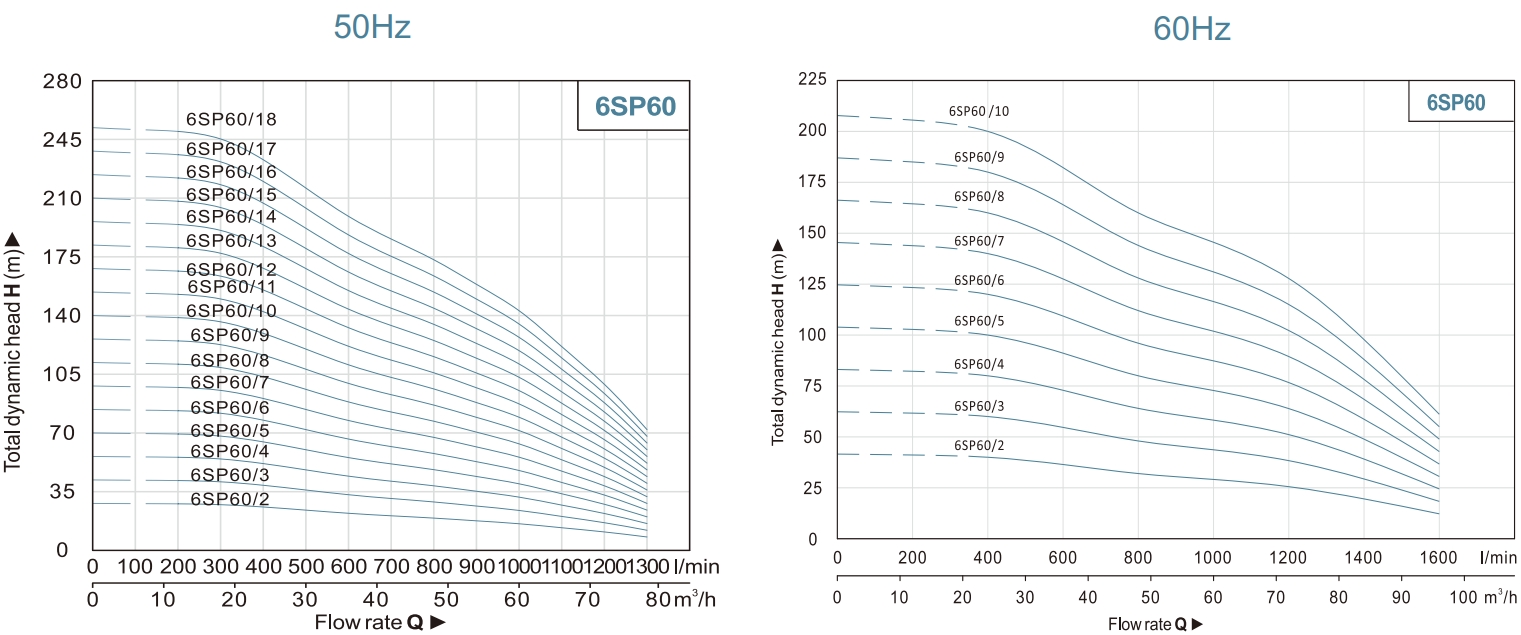

Model |

Power |

Deliver |

||||||||||||||||

|

1~220V/240V |

3~380V/415V |

KW |

HP |

Q(m³/h) |

0 |

6 |

12 |

18 |

24 |

30 |

36 |

42 |

48 |

54 |

60 |

66 |

72 |

78 |

|

Q(l/min) |

0 |

100 |

200 |

300 |

400 |

500 |

600 |

700 |

800 |

900 |

1000 |

1100 |

1200 |

1300 |

||||

|

6SPM60/2 |

6SP60/2 |

4 |

5.5 |

H(m) |

28 |

28 |

28 |

27 |

26 |

24 |

22 |

21 |

19 |

18 |

16 |

14 |

11 |

8 |

|

6SPM60/3 |

6SP60/3 |

5.5 |

7.5 |

42 |

42 |

42 |

41 |

39 |

36 |

33 |

31 |

29 |

26 |

23 |

20 |

16 |

11 |

|

|

- |

6SP60/4 |

7.5 |

10 |

56 |

56 |

56 |

55 |

52 |

48 |

44 |

41 |

38 |

35 |

31 |

26 |

21 |

15 |

|

|

- |

6SP60/5 |

9.2 |

15 |

70 |

70 |

69 |

68 |

65 |

60 |

55 |

52 |

48 |

44 |

39 |

33 |

26 |

18 |

|

|

- |

6SP60/6 |

11 |

15 |

84 |

84 |

83 |

82 |

78 |

72 |

66 |

62 |

58 |

53 |

47 |

40 |

31 |

22 |

|

|

- |

6SP60/7 |

13 |

17.5 |

98 |

98 |

97 |

95 |

91 |

84 |

77 |

72 |

67 |

62 |

55 |

46 |

36 |

25 |

|

|

- |

6SP60/8 |

15 |

20 |

112 |

112 |

111 |

109 |

104 |

96 |

89 |

83 |

77 |

71 |

63 |

53 |

42 |

29 |

|

|

- |

6SP60/9 |

18.5 |

25 |

126 |

125 |

125 |

123 |

116 |

108 |

100 |

93 |

87 |

79 |

70 |

60 |

47 |

33 |

|

|

- |

6SP60/10 |

18.5 |

25 |

140 |

139 |

139 |

136 |

129 |

120 |

111 |

103 |

96 |

88 |

78 |

66 |

52 |

36 |

|

|

|

6SP60/11 |

22 |

30 |

154 |

153 |

153 |

150 |

142 |

132 |

122 |

113 |

106 |

97 |

86 |

73 |

57 |

40 |

|

|

- |

6SP60/12 |

22 |

30 |

168 |

167 |

167 |

164 |

155 |

144 |

133 |

124 |

116 |

106 |

94 |

80 |

62 |

44 |

|

|

- |

6SP60/13 |

26 |

35 |

182 |

181 |

180 |

177 |

168 |

156 |

144 |

134 |

125 |

115 |

102 |

86 |

67 |

47 |

|

|

- |

6SP60/14 |

26 |

35 |

196 |

195 |

194 |

191 |

181 |

168 |

155 |

144 |

135 |

123 |

109 |

93 |

73 |

51 |

|

|

- |

6SP60/15 |

30 |

40 |

210 |

209 |

208 |

204 |

194 |

180 |

166 |

155 |

144 |

132 |

117 |

99 |

78 |

54 |

|

|

- |

6SP60/16 |

30 |

40 |

224 |

223 |

222 |

218 |

207 |

192 |

177 |

165 |

154 |

141 |

125 |

106 |

83 |

58 |

|

|

- |

6SP60/17 |

37 |

50 |

238 |

237 |

236 |

232 |

220 |

204 |

188 |

175 |

164 |

150 |

133 |

113 |

88 |

62 |

|

|

- |

6SP60/18 |

37 |

50 |

252 |

251 |

250 |

245 |

233 |

216 |

199 |

186 |

173 |

159 |

141 |

119 |

93 |

65 |

|

|

Model |

Power |

Deliver |

||||||||||

|

3~220V/380V |

KW |

HP |

Q(m³/h) |

0 |

12 |

24 |

36 |

48 |

60 |

72 |

84 |

96 |

|

Q(l/min) |

0 |

200 |

400 |

600 |

800 |

1000 |

1200 |

1400 |

1600 |

|||

|

6SP60/2 |

7.5 |

10 |

H(m) |

42 |

41 |

40 |

36 |

32 |

29 |

26 |

20 |

12 |

|

6SP60/3 |

9.2 |

12.5 |

62 |

61 |

60 |

55 |

48 |

44 |

38 |

29 |

18 |

|

|

6SP60/4 |

11 |

15 |

83 |

82 |

80 |

73 |

64 |

58 |

51 |

39 |

24 |

|

|

6SP60/5 |

15 |

20 |

104 |

103 |

100 |

91 |

80 |

73 |

64 |

49 |

30 |

|

|

6SP60/6 |

18.5 |

25 |

125 |

124 |

120 |

109 |

96 |

88 |

77 |

59 |

37 |

|

|

6SP60/7 |

22 |

30 |

146 |

144 |

140 |

127 |

112 |

102 |

90 |

69 |

43 |

|

|

6SP60/8 |

26 |

35 |

166 |

165 |

160 |

146 |

128 |

117 |

102 |

78 |

49 |

|

|

6SP60/9 |

26 |

35 |

187 |

185 |

180 |

164 |

144 |

131 |

115 |

88 |

55 |

|

|

6SP60/10 |

30 |

40 |

208 |

206 |

200 |

182 |

160 |

146 |

128 |

98 |

61 |

|

A submersible pump factory is responsible for producing pumps that operate fully underwater while maintaining stable per...

READ MOREA borehole pump manufacturer plays an important role in water supply systems, especially in areas where surface water is...

READ MOREWater drawn from deep underground plays a key role in agriculture, industry, and residential supply. Behind this process...

READ MORE

Water Shortage Protection Pressure range : 20-100psi Rated Current : 12A Rated ...

See Details

Starting pressure : 1.2bar - 3.0bar Max. Rated Current : 10A Max. Working Pressu...

See Details

Carbon steel flange Working temperature: -10°C~99°C (Butyl) -10°C~99°C (EPDM)

See Detailsaseriesnoisereductiondesignacid-baseverticalsurfacepump-1.jpg)

Identify noise sourcesAnalyze the operating conditionsUse noise reduction techni...

See Details

High Pressure Hot And Cold Water Circulation Pump Inlet/Outlet: 1.5" x 1.5" Body...

See Details

Mass Flow Solar Centrifugal Pump with DC Controller

See Details