4SPM5 4" High Efficiency Bearing Longer Life Rust-proof Stainless Steel Impeller Pencil Pump

View All Products

en

4SPM5 4" High Efficiency Bearing Longer Life Rust-proof Stainless steel impeller Borehole Submersible Pump is the perfect solution for extracting water from deep wells, ensuring a constant and reliable water supply for various applications. With its exceptional features and superior performance, this pump is a must-have for any cross-border e-commerce platform.

1、Its high efficiency bearing ensures a longer life span, making it a reliable investment for long-term use

2、 The rust-proof stainless steel impeller further enhances its durability, ensuring that it remains in pristine condition even in harsh environments.

3、Its powerful motor and high pressure capabilities allow for efficient water extraction, ensuring a steady flow of water for various purposes such as irrigation, domestic use, and industrial applications.

4、 Its user-friendly interface and simple controls make it suitable for both professionals and DIY enthusiasts. Whether you are a farmer, a homeowner, or a business owner, this pump is designed to cater to your specific needs.

5、Maximum fluid temperature up to +50℃

6、Maximum sand content : 0.25%

7、Minimum well diameter : 4"

1. Reversible electric motor

2. Single-phase: 110/220V/60Hz or Three-phase: 220/380V/60Hz

3. Comes equipped with either a starting control box or a digital automatic control box

4. Pumps are designed and tested for optimal casing stress considerations

5. Compliant with all relevant NEMA dimensional standards

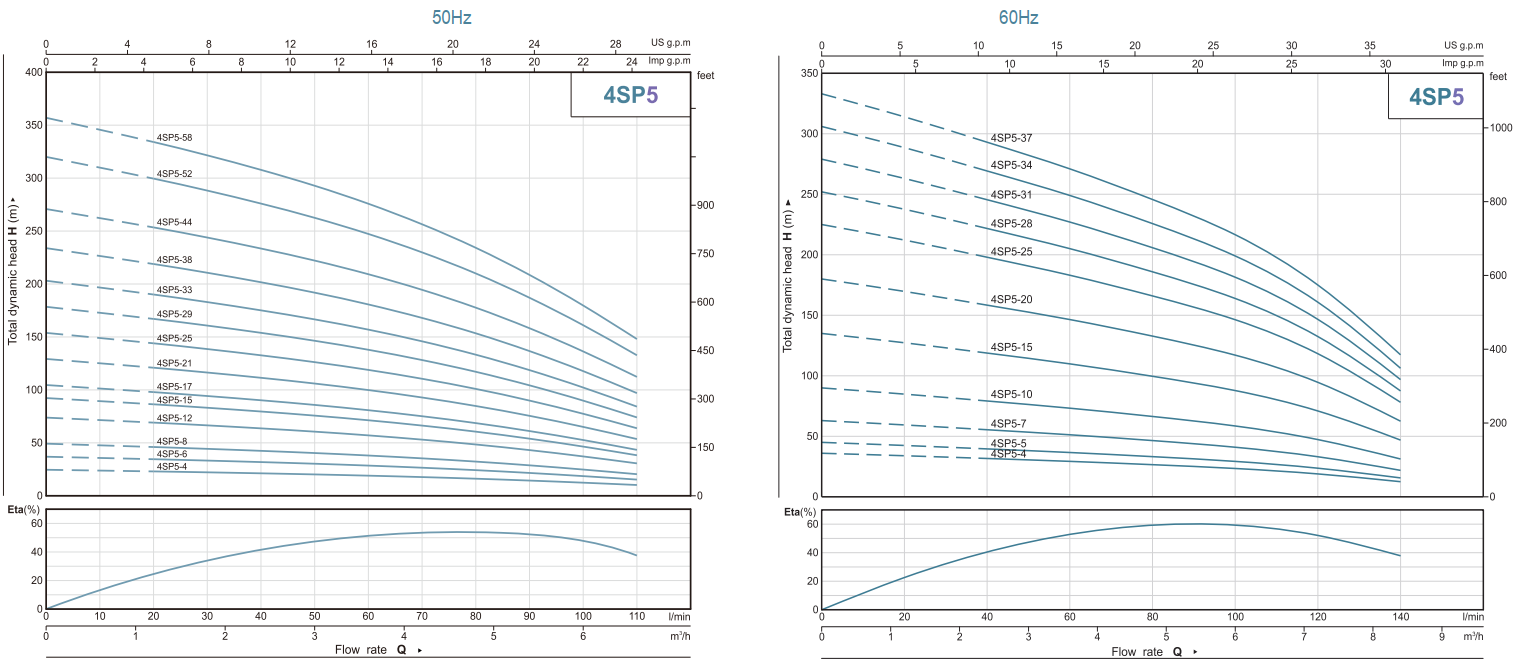

6. Curve tolerances strictly adhere to the guidelines outlined in ISO 9903.

Special mechanical seal

Other voltages or frequency 50Hz

Single phase motor with built-in capacitor

(according to our general sales conditions)

|

Materials Table |

||

|

NO. |

Part |

Material |

|

1 |

Pump external casing |

AISI 304 SS |

|

2 |

Delivery casing |

AISI 304 SS |

|

3 |

Suction lantern |

AISI 304 SS |

|

4 |

Diffuser |

AISI 304 SS |

|

5 |

Impeller |

AISI 304 SS |

|

6 |

Pump shaft |

AISI 304 SS |

|

7 |

Shaft coupling |

AISI 304 SS |

|

8 |

Wear ring |

Rubber |

|

9 |

Motor external casing |

AISI 304 SS |

|

10 |

Oil chamber |

Cast-Cu ASTM C85500 Cast-iron ASTM NO.30 AISI 304 SS |

|

11 |

Bottom support |

AISI 304 SS |

|

12 |

Mechanical Seal |

Special seal for deep well (Graphite-Ceramic) |

|

13 |

Seal lubricant oil |

Oil for food machinery and pharmaceutic use |

|

14 |

Motor shaft |

AISI 304 SS-ASTM 5140 |

|

Model |

Power |

Deliver |

||||||||||||||

|

1~220-240V |

3~380-415V |

KW |

HP |

Q(m³/h) |

0 |

0.6 |

1.2 |

1.8 |

2.4 |

3.0 |

3.6 |

4.2 |

4.8 |

5.4 |

6.0 |

6.6 |

|

Q(l/min) |

0 |

10 |

20 |

30 |

40 |

50 |

60 |

70 |

80 |

90 |

100 |

110 |

||||

|

4SPM5/4 |

4SP5/4 |

0.37 |

0.5 |

H(m)

|

25 |

24 |

23 |

22 |

21 |

20 |

19 |

18 |

16 |

15 |

12 |

10 |

|

4SPM5/6 |

4SP5/6 |

0.55 |

0.75 |

37 |

36 |

35 |

33 |

32 |

30 |

28 |

26 |

24 |

22 |

19 |

15 |

|

|

4SPM5/8 |

4SP5/8 |

0.75 |

1 |

49 |

48 |

46 |

44 |

42 |

40 |

38 |

35 |

32 |

29 |

25 |

20 |

|

|

4SPM5/12 |

4SP5/12 |

1.1 |

1.5 |

74 |

72 |

69 |

66 |

63 |

60 |

57 |

53 |

48 |

44 |

37 |

31 |

|

|

4SPM5/15 |

4SP5/15 |

1.3 |

1.75 |

92 |

89 |

86 |

83 |

79 |

75 |

71 |

66 |

61 |

55 |

47 |

38 |

|

|

4SPM5/17 |

4SP5/17 |

1.5 |

2 |

105 |

101 |

98 |

94 |

90 |

85 |

80 |

75 |

69 |

62 |

53 |

44 |

|

|

4SPM5/21 |

4SP5/21 |

1.8 |

2.5 |

129 |

125 |

121 |

116 |

111 |

105 |

99 |

92 |

85 |

76 |

66 |

54 |

|

|

4SPM5/25 |

4SP5/25 |

2.2 |

3 |

154 |

149 |

144 |

138 |

132 |

125 |

118 |

110 |

101 |

91 |

78 |

64 |

|

|

4SPM5/29 |

4SP5/29 |

2.6 |

3.5 |

179 |

173 |

167 |

160 |

153 |

145 |

137 |

128 |

117 |

106 |

90 |

74 |

|

|

4SPM5/33 |

4SP5/33 |

3 |

4 |

203 |

197 |

190 |

182 |

174 |

165 |

156 |

145 |

133 |

120 |

103 |

84 |

|

|

- |

4SP5/38 |

3.7 |

5 |

234 |

226 |

219 |

210 |

201 |

190 |

179 |

167 |

154 |

138 |

119 |

97 |

|

|

- |

4SP5/44 |

4 |

5.5 |

271 |

262 |

253 |

243 |

232 |

220 |

208 |

194 |

178 |

160 |

137 |

112 |

|

|

- |

4SP5/52 |

5 |

7 |

320 |

310 |

300 |

287 |

275 |

260 |

245 |

229 |

210 |

189 |

162 |

133 |

|

|

- |

4SP5/58 |

5.5 |

7.5 |

357 |

346 |

334 |

320 |

306 |

290 |

274 |

255 |

234 |

211 |

181 |

148 |

|

|

Model |

Power |

Deliver |

||||||||||

|

1~220/240V |

3~380/415V |

KW |

HP |

Q(m³/h) |

0 |

1.2 |

2.4 |

3.6 |

4.8 |

6.0 |

7.2 |

8.4 |

|

Q(l/min) |

0 |

20 |

40 |

60 |

80 |

100 |

120 |

140 |

||||

|

4SPM5/4 |

4SP5/4 |

0.55 |

0.75 |

H(m) |

36 |

34 |

32 |

29 |

27 |

23 |

19 |

12 |

|

4SPM5/5 |

4SP5/5 |

0.75 |

1 |

45 |

42 |

40 |

36 |

34 |

29 |

24 |

16 |

|

|

4SPM5/7 |

4SP5/7 |

1.1 |

1.5 |

63 |

59 |

55 |

51 |

57 |

41 |

33 |

22 |

|

|

4SPM5/10 |

4SP5/10 |

1.5 |

2 |

90 |

85 |

79 |

73 |

68 |

59 |

47 |

31 |

|

|

4SPM5/15 |

4SP5/15 |

2.2 |

3 |

135 |

127 |

119 |

110 |

101 |

88 |

71 |

47 |

|

|

- |

4SP5/20 |

3 |

4 |

180 |

170 |

158 |

146 |

134 |

117 |

95 |

62 |

|

|

- |

4SP5/25 |

4 |

5.5 |

225 |

S |

198 |

183 |

168 |

146 |

118 |

78 |

|

|

- |

4SP5/28 |

5 |

7 |

252 |

238 |

222 |

205 |

188 |

164 |

132 |

87 |

|

|

- |

4SP5/31 |

5.5 |

7.5 |

279 |

263 |

245 |

227 |

208 |

181 |

147 |

97 |

|

|

- |

4SP5/34 |

7 |

10 |

306 |

289 |

269 |

249 |

228 |

199 |

161 |

106 |

|

|

- |

4SP5/37 |

7.5 |

10 |

333 |

314 |

293 |

271 |

248 |

217 |

175 |

116 |

|

A submersible pump factory is responsible for producing pumps that operate fully underwater while maintaining stable per...

READ MOREA borehole pump manufacturer plays an important role in water supply systems, especially in areas where surface water is...

READ MOREWater drawn from deep underground plays a key role in agriculture, industry, and residential supply. Behind this process...

READ MORE

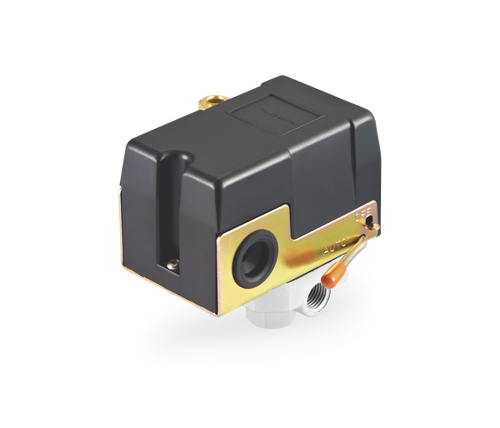

Starting pressure : 1.2bar - 3.0bar Max. Rated Current : 10A/30A Max. Working Pr...

See Details

Air-relief Customized Setting Pressure Switch for Air Compressors Pressure ran...

See Details

Starting pressure : 1.2bar - 3.0bar Max. Rated Current : 10A Max. Working Pressu...

See Details

Energy Saving Hot And Cold Water Circulation Pump Inlet / Outlet: 1.5" x 1.5" Bo...

See Details

Strong driving force Brass Impeller Self-priming JET Pump pump with Gasket

See Details

6" Size AC/DC With Water Filled Motor Permanent Magnet Brushless

See Details