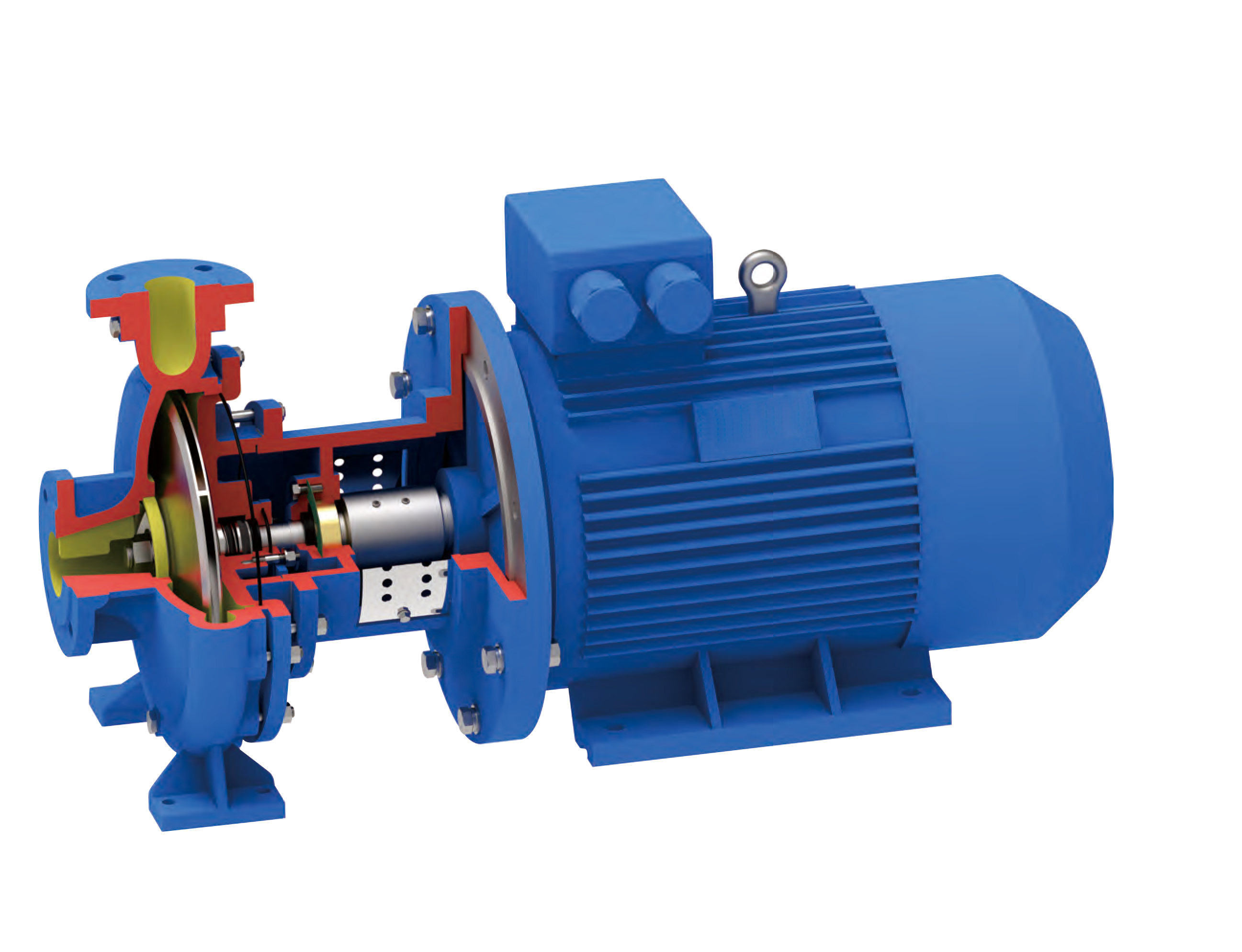

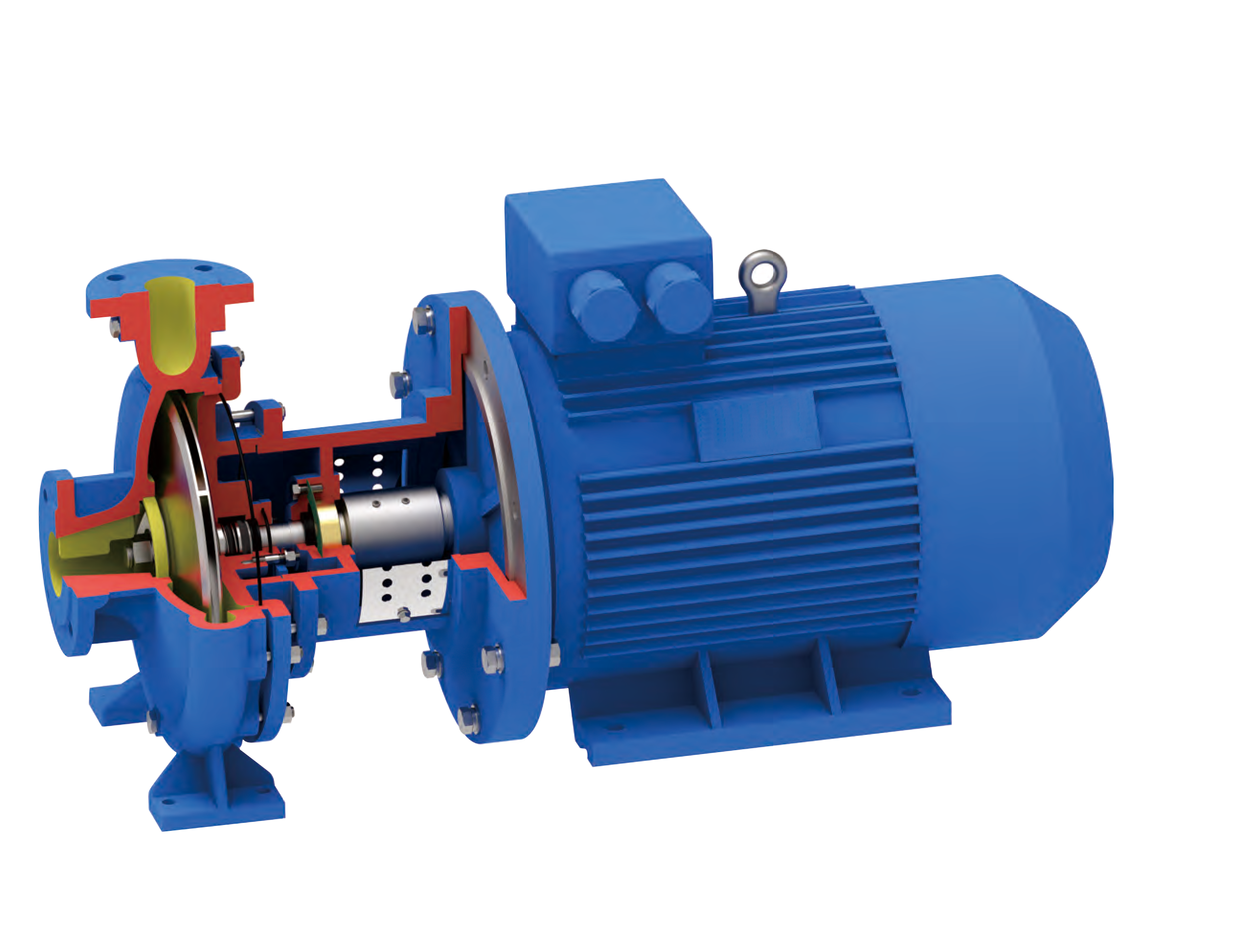

EAC Series Close-coupled Direct Connection Simplified Structure HonEnd Suction Centrifugal Pump

View All Products

en

Clean Water

Close-coupled Direct Connection

Simplified Structure

Horizontal Single Stage

End Suction Centrifugal Pump

The EAC Series Centrifugal Pump is an innovative solution designed for the efficient and cost-effective pumping of clean, thin liquids. As part of EDWIN Pump's Combi-system, it adheres to the Din24255/En 733 standards, ensuring a high degree of part interchangeability within the EA series pump constructions.

High Interchangeability: Benefits from a modular design that allows for easy part replacement and maintenance, reducing downtime and service costs.

Compact Design: The pump's close-coupled configuration with IEC standard electric motors saves space and simplifies installation.

Versatile Application: Suitable for a variety of liquids, including low-viscosity, clean, slightly contaminated, and aggressive fluids.

Low Maintenance: Thanks to its simple component layout and the inclusion of a mechanical seal, the EAC pump requires minimal upkeep.

Back Pull Out Feature: Allows for easy removal of the rotating assembly without the need to disconnect the pump from the piping system, further reducing maintenance time and effort.

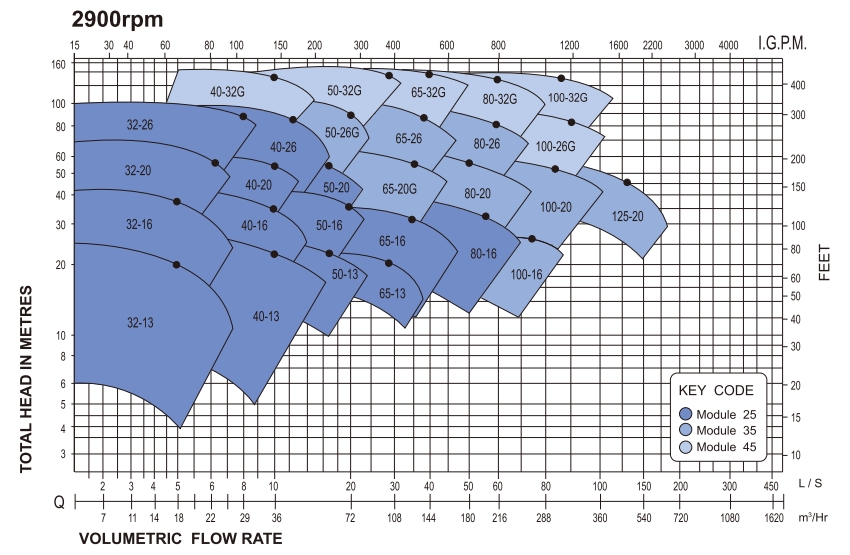

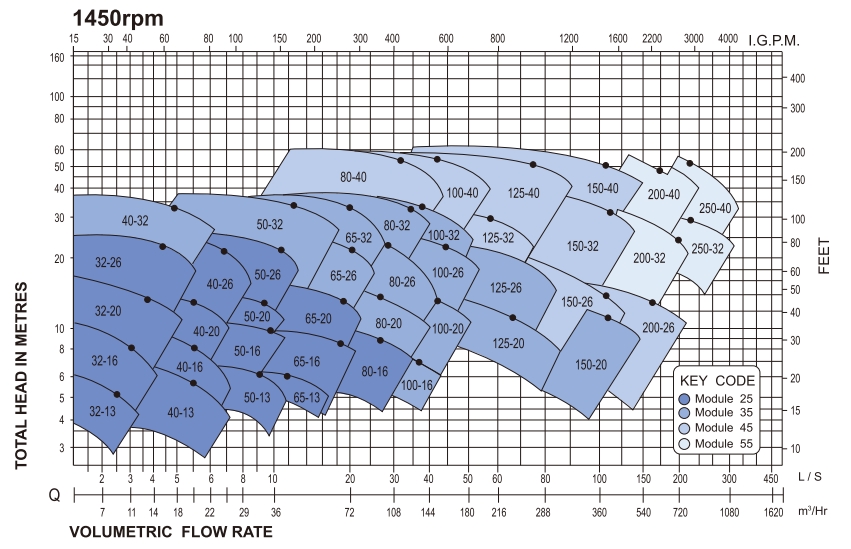

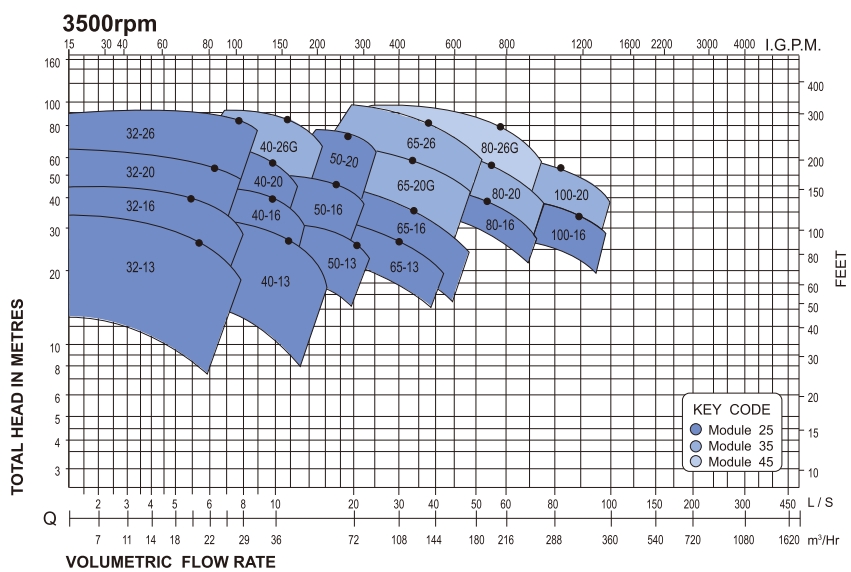

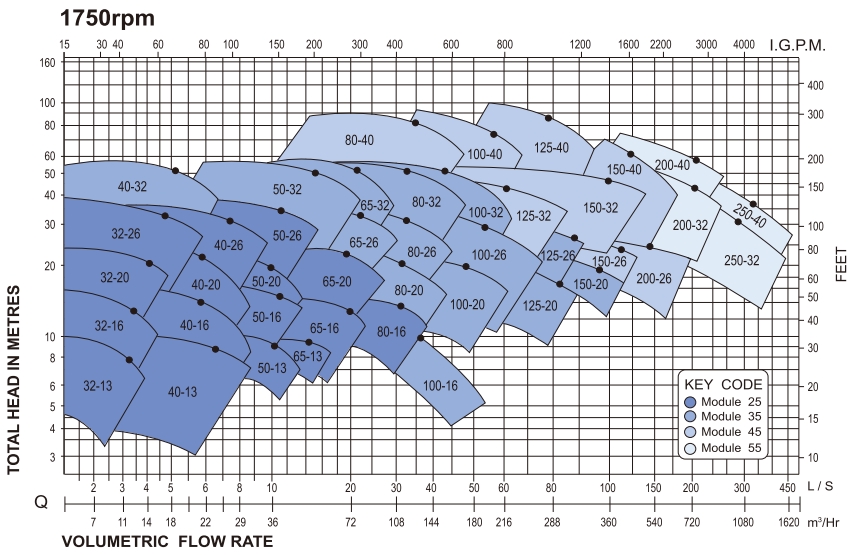

Maximum Flow Rate: Up to 1100 m³/h, ensuring high throughput for various applications.

Head Capacity: Capable of reaching up to 150 meters, suitable for high-lift scenarios.

Temperature Tolerance: Operates effectively within a range of -10°C to +105°C, making it versatile for different environmental conditions.

Service Pressure: Can handle pressures up to 16 bar, depending on the specific model, providing robust performance for demanding applications.

2. For the determination of the drive power werecommend the following additional power:

-up to 4 kW : 25 % ;

-4 up to 7.5 kW : 20 % ;

-7.5 up to 37 kW : 15 % ;

-Above 37kw : 10%

Please note : The max. motor power allowed for some construction sizes as shown in the individual curves

Temperature Range: -10°C to +105°C

Service Pressure: Up to 16 bar (model dependent)

Applications :

The EAC Series pump is ideal for use in crop farming, market gardening, on board ships, and in the handling of various chemicals. Its versatility makes it a valuable asset in industries that require reliable and efficient liquid handling solutions.

Maintain :

The EAC pump's design, with a small number of components and the use of a mechanical seal, minimizes the need for frequent maintenance. The Back Pull Out feature of the rotating assembly further enhances the ease of maintenance, making it a user-friendly option for long-term use.

CE Cerificate :

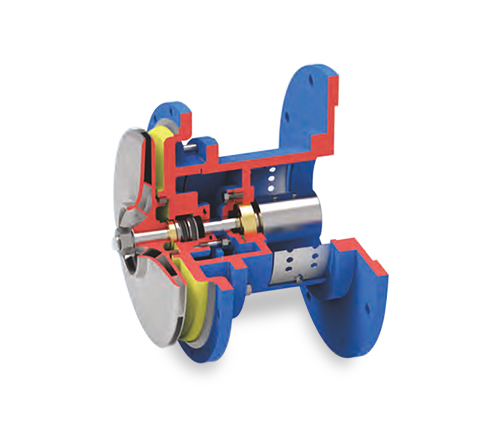

Pump casing

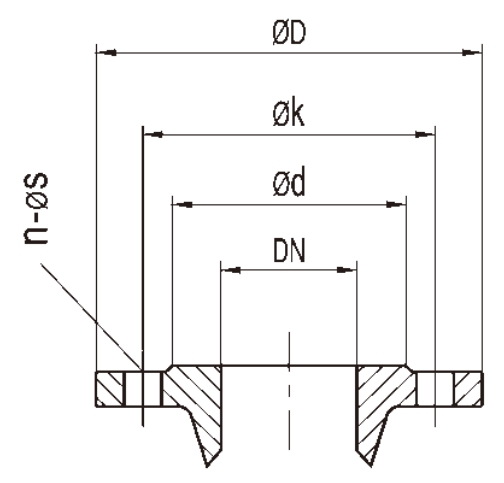

Flanges according to lSO 7005

Max.working pressure 10 bar

Drain opening

Wide range of applications

Complete and fast draining of the casing

Pump cover

O-ring seal, fully chambered

Machined fits

Perfectly aligned

Suction capabilities

Smooth suction entry in pump casing

Smooth surface

Anti rotation vane

Optimum suction capabilities

Minimal flow distortion giving better suction capabilities

Impeller locking

Impeller nut with lock washer

Reliable locking

Hydraulic balancing

Flat cover for hydraulic balancing

Back vanes for hydraulic balancing

Extended bearing life time

Foot

Machined foot

Exact positioning on base and in pipework

Wear rings

Replaceable wear rings are fitted as standard to all casing and also casing cover on larger pumps which reduces maintenance and cost

Coupling guard

Consisting of 2 identical parts with snap fit

Stainless steel

Quick and easy mounting

for increased safety

Non sparking

|

DN |

Ød |

Øk |

ØD |

n |

ØS |

|

32 |

73 |

100 |

140 |

4 |

18 |

|

40 |

83 |

110 |

150 |

4 |

18 |

|

50 |

98 |

125 |

165 |

4 |

18 |

|

65 |

118 |

145 |

185 |

4 |

18 |

|

80 |

133 |

160 |

200 |

8 |

18 |

|

100 |

153 |

180 |

220 |

8 |

18 |

|

125 |

183 |

210 |

250 |

8 |

18 |

|

150 |

209 |

240 |

285 |

8 |

22 |

|

200 |

264 |

295 |

340 |

12 |

22 |

|

250 |

320 |

355 |

405 |

12 |

26 |

|

300 |

375 |

410 |

460 |

12 |

26 |

|

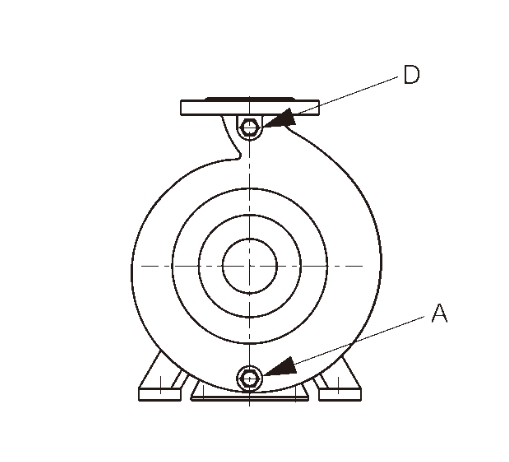

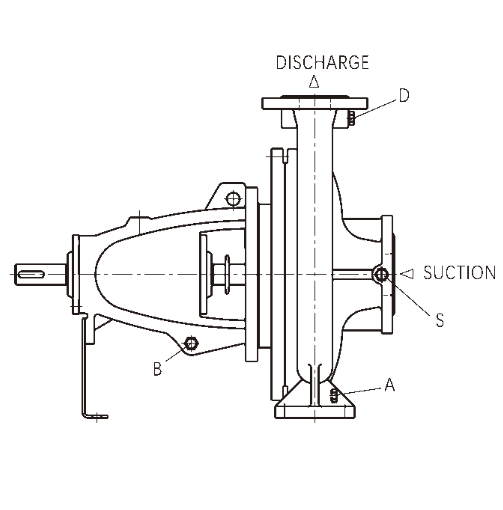

Pump Model |

A |

B |

D |

S |

|

Casing Drain |

Housing Drain |

Gauge Drain |

Gauge Drain |

|

|

32-13 |

1/4 |

1/4 |

1/4 |

1/4 |

|

32-16 |

1/4 |

1/4 |

1/4 |

1/4 |

|

32-20 |

1/4 |

1/4 |

1/4 |

1/4 |

|

32-26 |

1/4 |

1/4 |

1/4 |

1/4 |

|

40-13 |

1/4 |

1/4 |

1/4 |

1/4 |

|

40-16 |

1/4 |

1/4 |

1/4 |

1/4 |

|

40-20 |

1/4 |

1/4 |

1/4 |

1/4 |

|

40-26 |

1/4 |

1/4 |

1/4 |

1/4 |

|

40-32 |

1/4 |

1/4 |

1/4 |

1/4 |

|

40-32G |

1/4 |

1/4 |

1/4 |

1/4 |

|

50-13 |

1/4 |

1/4 |

1/4 |

1/4 |

|

50-16 |

1/4 |

1/4 |

1/4 |

1/4 |

|

50-20 |

1/4 |

1/4 |

1/4 |

1/4 |

|

50-26 |

1/4 |

1/4 |

1/4 |

1/4 |

|

50-26G |

1/4 |

1/4 |

1/4 |

1/4 |

|

50-32 |

1/4 |

1/4 |

1/4 |

1/4 |

|

50-32G |

1/4 |

1/4 |

1/4 |

1/4 |

|

65-13 |

1/4 |

1/4 |

1/4 |

1/4 |

|

65-16 |

1/4 |

1/4 |

1/4 |

1/4 |

|

65-20 |

1/4 |

1/4 |

1/4 |

1/4 |

|

65-20G |

1/4 |

1/4 |

1/4 |

1/4 |

|

65-26 |

1/4 |

1/4 |

1/4 |

1/4 |

|

65-32 |

1/4 |

1/4 |

1/4 |

1/4 |

|

65-32G |

1/4 |

1/4 |

1/4 |

1/4 |

|

80-16 |

1/4 |

1/4 |

1/4 |

1/4 |

|

80-20 |

1/4 |

1/4 |

1/4 |

1/4 |

|

80-26 |

1/4 |

1/4 |

1/4 |

1/4 |

|

80-32 |

1/4 |

1/4 |

1/4 |

1/4 |

|

80-32G |

1/4 |

1/4 |

1/4 |

1/4 |

|

80-40 |

1/4 |

1/4 |

1/4 |

1/4 |

|

100-16 |

3/8 |

1/4 |

1/4 |

1/4 |

|

100-20 |

3/8 |

1/4 |

1/4 |

1/4 |

|

100-26 |

3/8 |

1/4 |

1/4 |

1/4 |

|

100-26G |

3/8 |

1/4 |

1/4 |

1/4 |

|

100-32 |

3/8 |

1/4 |

1/4 |

1/4 |

|

100-32G |

3/8 |

1/4 |

1/4 |

1/4 |

|

100-40 |

3/8 |

1/4 |

1/4 |

1/4 |

|

125-20 |

3/8 |

1/4 |

1/4 |

1/4 |

|

125-26 |

3/8 |

1/4 |

1/4 |

1/4 |

|

125-32 |

3/8 |

1/4 |

1/4 |

1/4 |

|

125-40 |

3/8 |

1/4 |

1/4 |

1/4 |

|

150-20 |

3/8 |

1/4 |

1/4 |

1/4 |

|

150-26 |

3/8 |

1/4 |

1/4 |

1/4 |

|

150-32 |

3/8 |

1/4 |

1/4 |

1/4 |

|

150-40 |

3/8 |

1/4 |

1/4 |

1/4 |

|

200-26 |

3/8 |

1/4 |

1/4 |

1/4 |

|

200-32 |

3/8 |

1/4 |

1/4 |

1/4 |

|

200-40 |

3/8 |

1/4 |

1/4 |

1/4 |

|

250-32 |

3/8 |

1/4 |

1/4 |

1/4 |

|

250-40 |

3/8 |

1/4 |

1/4 |

1/4 |

A borehole pump manufacturer plays an important role in water supply systems, especially in areas where surface water is...

READ MOREWater drawn from deep underground plays a key role in agriculture, industry, and residential supply. Behind this process...

READ MOREEfficient irrigation plays a key role in modern agriculture, landscaping, and water management projects. An experienced ...

READ MORE

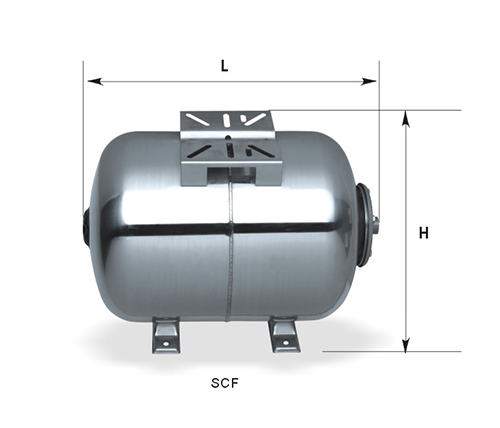

Carbon steel flange Working temperature: -10°C~99°C (Butyl) -10°C~99°C (EPDM) 0°...

See Details

Carbon steel flange Working temperature: -10°C~99°C (Butyl) -10°C~99°C (EPDM)

See Details

Stainless steel Working temperature: -20°C~99°C (Butyl) -20°C~99°C (EPDM) 0°C~77...

See Detailsserieswatershortageprotectionvoltagestabilizationstainlesssteelverticalmultistagepump.jpg)

Water Shortage ProtectionVoltage StabilizationStainless Steel ConstructionVertic...

See Details

Low Noise Hot And Cold Water Circulation Pump Inlet / Outlet: 2" Body length: 18...

See Details

Strong driving force Brass Impeller Self-priming JET Pump pump with Gasket

See Details