EISO Series SS Large Bearing Back Pull-Out End Suction Centrifugal Pump for Water Pressure

View All Products

en

SS Impeller

Large Bearing Back Pull-Out

End Suction Centrifugal Pump

for Water Pressure

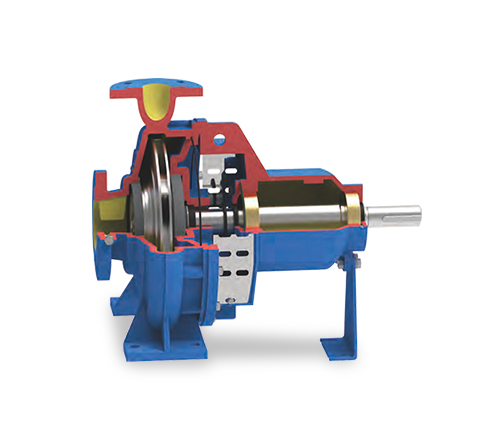

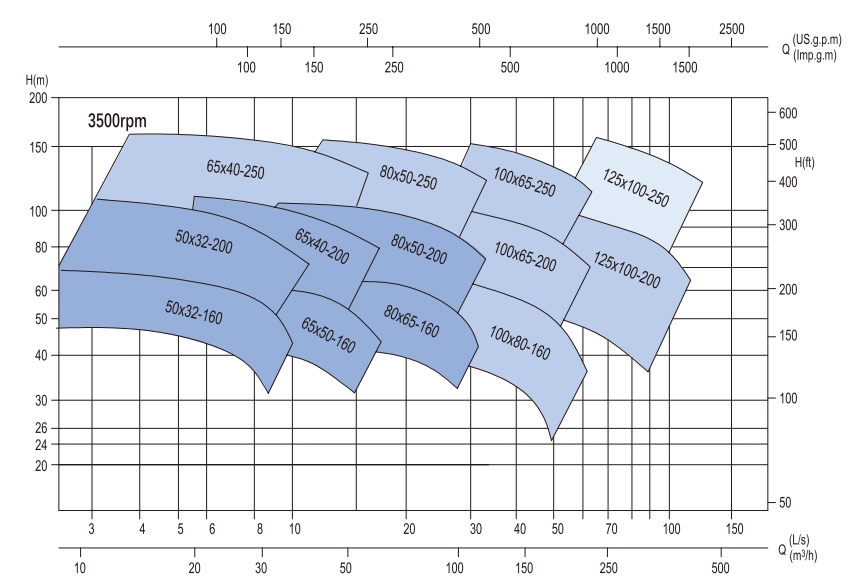

The EISO Series SS (Stainless Steel) Large Bearing Back Pull-Out End Suction Centrifugal Pump is engineered to provide a high-performance, durable, and reliable solution for water pressure applications. This pump is designed to meet the international standards of ISO2858/5199, ensuring compatibility and interchangeability with other pumps within the EISO series.

Stainless Steel Construction: The pump is made from high-quality stainless steel, offering excellent corrosion resistance and durability.

Large Bearing Design: Equipped with large bearings to handle higher loads and ensure smooth operation, which is essential for pumps operating at higher pressures.

Back Pull-Out Mechanism: Allows for easy removal of the rotating assembly without disturbing the piping system, reducing maintenance time and costs.

End Suction Design: The axial suction port design ensures efficient fluid intake, which is crucial for maintaining optimal pump performance.

Applications :

The EISO Series SS pump is versatile and can be applied across a spectrum of industries:

Water Supply Systems: For municipal and industrial water distribution, ensuring consistent water pressure.

Fire Fighting Systems: To provide high-pressure water for firefighting efforts, crucial for emergency response.

Pressure Boosting: To increase water pressure in systems for better distribution and performance.

Heating Systems for Commercial District Heating: To circulate hot water in heating networks, providing efficient heat distribution.

General Transport for Industrial Processes: To move fluids in various industrial applications, including those requiring high-pressure water.

Cooling Plants for Industrial Processing and Air-Conditioning Units: To manage cooling requirements in industrial and HVAC systems, ensuring optimal performance.

Maintains :

Compact Configuration: The pump and electric motor assembly are designed for space efficiency, making it suitable for installations with limited space.

Standard IEC Electric Motors: The use of a stub shaft allows for the use of standard IEC electric motors, simplifying the selection and replacement process.

Mechanical Seal: Reduces the need for frequent maintenance, ensuring a low total cost of ownership.

Back Pull Out Feature: Enables the removal of the rotating assembly without disconnecting the pump from the piping, streamlining maintenance procedures.

CE Cerificate :

|

Components |

Materials |

|

Pump body |

Cast iron/ Stainless steel |

|

Impeller |

Cast iron/ Stainless steel |

|

Shaft |

Stainless steel |

|

Shaft seal |

Mechanical Seal |

|

Bearing lubrication |

Grease Life |

|

Bearing Brand |

NTN |

Pump Casing

highly efficient cast iron wolute casings,with flanges rated to PN1.6MPa (16bar),drilled to lS07005.2:1988).

Enlarge Shaft

reduces shaft deflection.Standard in 420SS,3045S&316SS as an option.Tapered & keyed shaft design allowing ease of removalin maintenance & positive locking whilst in operation

Bearings

Heavy duty NTN or approved equivalent, greased forlife, reducing maintenance. Protected by a qualitymanufactured lip seal reducing ingress of moisture orforeign matter. Housed within removable bearing capcover assembly

Bearing housing

Robust/heavy duty,manufactured in high strengthcast iron providing trouble-free life complete withlifting provision and support foot.

Shaft seal

Single, high quality john Crane or approved equivalentmechanical seal with carbon vs ceramic/viton fitted asstandard to all ElSO Series pumps with other optionssuch as Silicone vs Silicone or high temp also available.

Wear Ring

Cast lron wear rings - fitted as standard,replaceable front & rear wear rings with optionalmaterials, for a trouble-free lifecycle.

Casing O-Ring

Re-usable o-rings in Nitrile for ease of re-assembly

Tappings

Convenient suction & discharge pressure gaugetappings plus volute drain, fitted as standard toall ElSO Series pumps.

Painting

Prior to painting, the pump is thoroughly cleaned offoreign material. The pump is then painted with ahigh quality/undercoat/ primer and industrial enamelpaint.

Impeller

Cast lron/SS304/SS316 impeller-fitted as standard, in aclosed design is fitted as standard to prevent corrosion instationary or inactive situations. The use of 3-D solid mode(CAD) Computer Aided Design and (CFD) ComputationalFluid Dynamics ensures high efficiencies, reducing overallrunning costs.lmpeller diameters can be trimmed to suitspecified performance. ElSO impellers are dynamicallybalanced, providing smooth, vibration free operation,preventing premature bearing failure.

Optional :

|

NO |

Part Name |

|

1 |

Pump Casing |

|

2.1/2.2 |

Wear Ring |

|

3 |

Impeller |

|

4 |

O-Ring |

|

5.1 |

Casing Cover |

|

5.2 |

Casing Cover (Double Mech seal) |

|

5.3 |

Casing Cover(Gland Packing) |

|

5.4 |

Casing Cover(Cartridge seal) |

|

5.5 |

Casing Cover(Dynamic seal) |

|

6.1/6.2 |

Deep groove ball bearing |

|

6.3 |

Cylindrical roller bearing |

|

6.4 |

Angular contact ball bearing |

|

7 |

Nameplate |

|

8/8.1 |

Bearing Housing |

|

9 |

Oil Seal |

|

10 |

Shaft |

|

11 |

Impeller Key |

|

12 |

Support Foot |

|

13 |

Bearing cover |

|

14 |

Slinger |

|

15 |

Single mechanical seal |

|

16 |

Woodruff key |

|

17 |

Impeller Washer |

|

18 |

Impeller Nut |

|

19 |

Oil hole cover |

|

20 |

Tab washer |

|

21 |

Nut |

|

22 |

Oil indicator |

|

23 |

Drain plug |

|

24.2 |

Seal Gland |

|

26.2 |

Mech. Shaft sleeve |

|

26.3 |

Packing. Shaft Sleeve |

|

27 |

Double mechanical seal |

|

28 |

Packing Gland |

|

29 |

Gland Packing |

|

30 |

Lantern Ring |

|

31 |

Cartridge seal |

|

32 |

Seal plate |

|

33 |

Vice impeller |

|

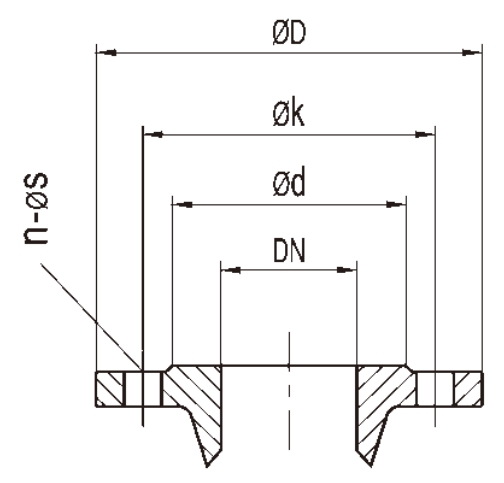

DN |

Ød |

Øk |

ØD |

n |

ØS |

|

32 |

76 |

100 |

140 |

4 |

18 |

|

40 |

84 |

110 |

150 |

4 |

18 |

|

50 |

99 |

125 |

165 |

4 |

18 |

|

65 |

118 |

145 |

185 |

4 |

18 |

|

80 |

132 |

160 |

200 |

8 |

18 |

|

100 |

156 |

180 |

220 |

8 |

18 |

|

125 |

184 |

210 |

250 |

8 |

18 |

|

150 |

211 |

240 |

285 |

8 |

22 |

|

200 |

266 |

295 |

340 |

12 |

22 |

|

250 |

319 |

355 |

405 |

12 |

26 |

|

300 |

370 |

410 |

460 |

12 |

26 |

|

350 |

429 |

470 |

520 |

16 |

26 |

A borehole pump manufacturer plays an important role in water supply systems, especially in areas where surface water is...

READ MOREWater drawn from deep underground plays a key role in agriculture, industry, and residential supply. Behind this process...

READ MOREEfficient irrigation plays a key role in modern agriculture, landscaping, and water management projects. An experienced ...

READ MORE

Carbon steel flange Working temperature: -10°C~99°C (Butyl) -10°C~99°C (EPDM) 0°...

See Details

Stainless steel Working temperature: -20°C~99°C (Butyl) -20°C~99°C (EPDM) 0°C~77...

See Details

Antirust treatment Copper winding Thermal protector C&U Bearing

See Detailsserieswatershortageprotectionvoltagestabilizationstainlesssteelverticalmultistagepump.jpg)

Water Shortage ProtectionVoltage StabilizationStainless Steel ConstructionVertic...

See Details

Low Noise Hot And Cold Water Circulation Pump Inlet / Outlet: 2" Body length: 18...

See Details

Rated voltage : 380V Motor power : 1.5kW-5.5kW Intelligent Drainage and Slurry P...

See Details