ECC Series SS Sea Water End Suction Horizontal Centrifugal Pump For Light Chemical Industrial

View All Products

en

SS Pump Body and Impeller

Sea Water and Sewage

End Suction Horizontal Centrifugal Pump

For Light Chemical Industrial

The ECC Series SS (Stainless Steel) Sea Water End Suction Horizontal Centrifugal Pump is designed for light chemical industrial applications where durability and corrosion resistance are paramount. This pump is built to handle the unique challenges posed by sea water and light chemical environments, ensuring a robust and long-lasting performance.

Stainless Steel Construction: The pump is constructed from stainless steel, providing superior resistance to corrosion and making it suitable for sea water and chemical applications.

End Suction Design: The axial suction port design ensures efficient fluid intake, which is crucial for maintaining optimal pump performance in challenging conditions.

Horizontal Centrifugal: The horizontal design allows for easy installation and maintenance, with the centrifugal action providing high efficiency in fluid movement.

Interchangeability: The ECC Series pumps are designed to be interchangeable with other similar pumps, conforming to international standards ISO5199/2858, EN 25199/22858, and DIN24256, ensuring flexibility and ease of replacement.

Applications :

The ECC centrifugal pump is suitable forhandling water or similar liquids mainly usedin the following.

Chemical and Petrochemical Industry: For handling chemicals and petrochemicals with ease.

Oil Refining Plants: To manage the transfer of sea water and chemicals in refining processes.

Paper Making Industry: To handle the water and chemical requirements in paper production.

Sugar Industry: For processing water and chemicals in sugar production.

Waste Water Treatment: To manage the treatment of sea water and chemical waste.

Pharmaceutical Food Industry: To ensure the purity and safety of water and chemicals used in pharmaceuticals and food processing.

Pumped Liquids :

-Water

-Acid

-Alkaline

-Ammonia

-Other corrsive and abrasive liquids

CE Cerificate :

|

Components |

Materials |

|

Pump body |

Stainless steel 304/316/316L/2205/2507 |

|

Impeller |

Stainless steel 304/316/316L/2205/2507 |

|

Shaft |

Stainless steel |

|

Shaft seal |

Mechanical Seal |

|

Bearing lubrication |

Grease Life,Grease, Oil lubrication |

|

Bearing Brand |

NTN |

Impeller/Shaft connection and seal

The impeller and shaft are fitted with taper,which increase the strength of the shaft

Impeller/ Casing

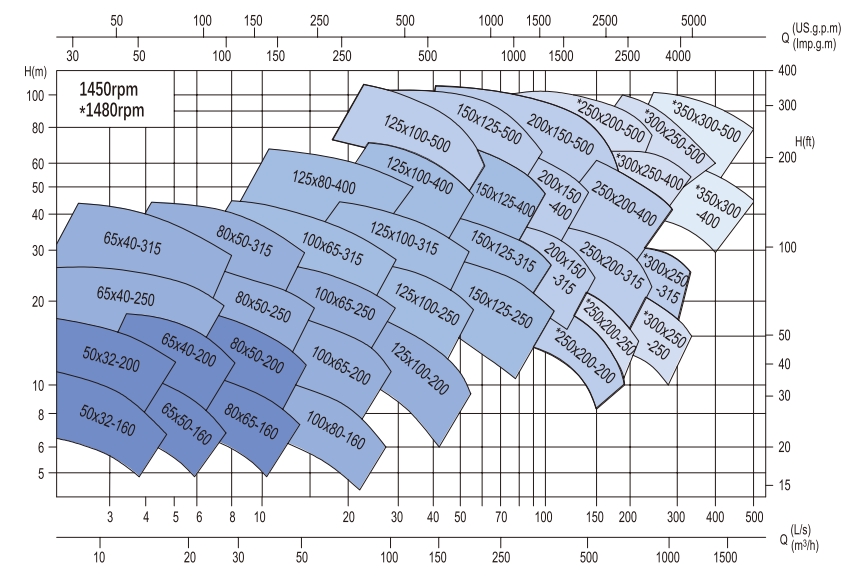

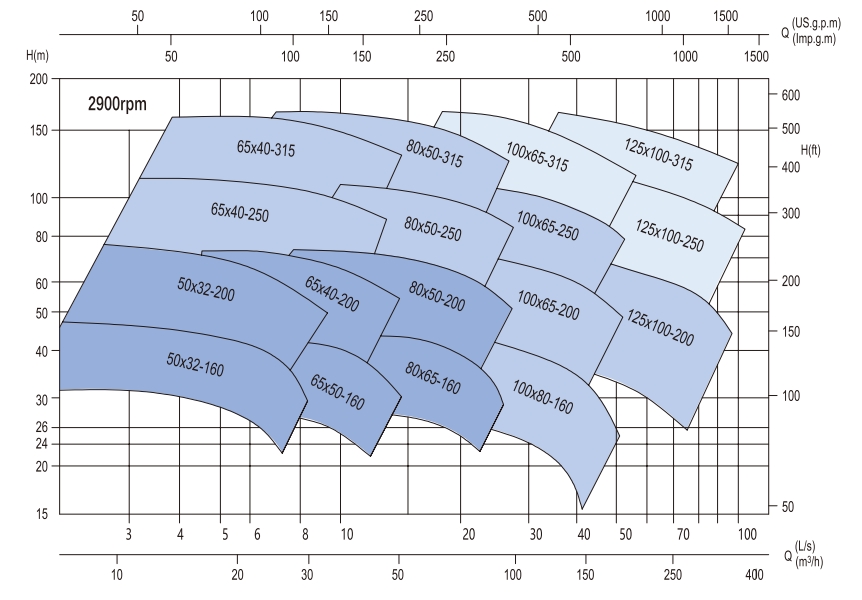

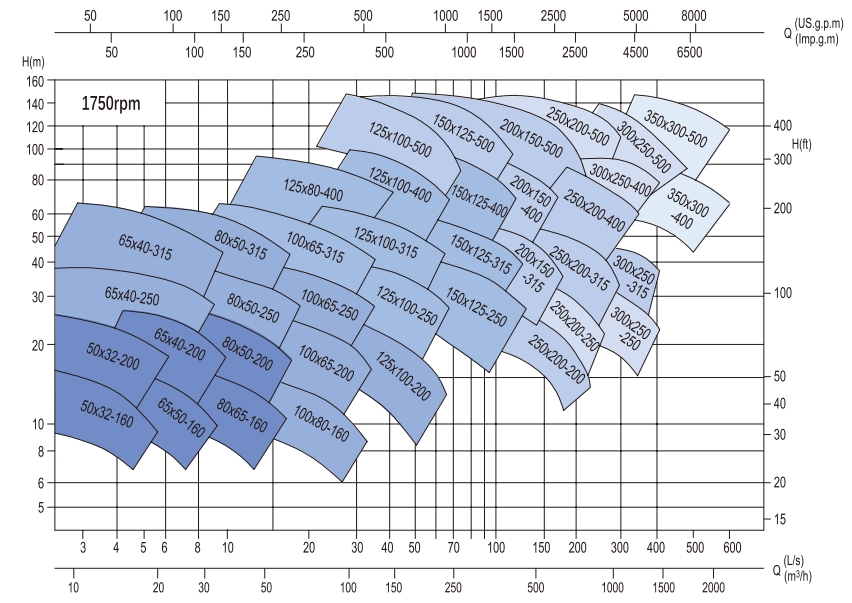

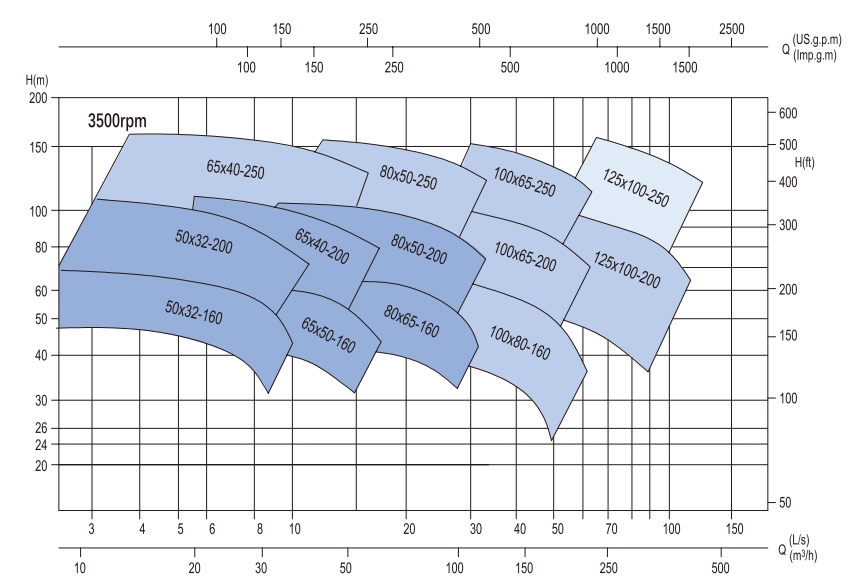

Optimized Hydraulic design with impeller diameter up to 547mm,ECC pumps have wider performance coverage than EN 25199/22858

Shaft seal

Single,Double mechanical seal,Cartridge mechanicalseal,Gland packing are available

Axial Force Balance

The axial force are mostly balance by the front/rear wearingrings and balanceing holes in impeller design, The residual axial force are balanced by the back to back arranged contactball bearings at the drive end.

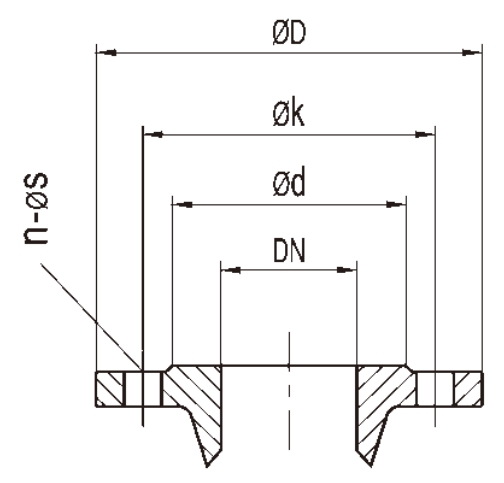

Flange

Flange dimensions comply to lSO 7005-1:1992 PN16 Mpa as standard,other flange (including ANSl flange) are also available by request

Heavy Duty Bearings

Cylindrical roller bearing at the impeller end, two of angularcontact ball bearing (back to back arrangment) at the drive end.Design bearing life up to 25000 hours.

Optional :

|

NO |

Part Name |

|

1 |

lmpeller Nut |

|

2 |

Impeller Washer |

|

3 |

Woodruff key |

|

4 |

Impeller |

|

5 |

Pump Casing |

|

6.1 |

Casing Cover(Single/Double mech seal) |

|

6.2 |

Casing Cover(Packing seal) |

|

6.3 |

Casing Cover(Cartridge Seal) |

|

6.4 |

Casing Cover(Dynamic seal) |

|

7.1 |

Bearing Housing (Standard) |

|

7.2 |

Bearing Housing(Heavy duty) |

|

8.1/8.2 |

Deep groove ball bearing |

|

8.3 |

Cylindrical roller bearing |

|

8.4 |

Angular contact ball bearing |

|

9 |

Nameplate |

|

10.1 |

Shaft(standard) |

|

10.2 |

Shaft(Heavy) |

|

11.1-11.5 |

Oil Seal |

|

12.1/12.2 |

Key |

|

13.1/13.2 |

Support Foot |

|

14.1-14.3 |

Gasket Paper |

|

15.1-15.3 |

Bearing Cover |

|

16.1-16.3 |

O-Ring |

|

17.1/17.2 |

Wear Ring |

|

18.1/18.2 |

Drain plug |

|

19 |

Oil hole cover |

|

20 |

Tab washer |

|

21 |

Nut |

|

22 |

Oil indicator |

|

23.1/23.2 |

Seal Gland |

|

24 |

Single Mechanical seal |

|

25.1 |

Shaft Sleeve (Single mech.) |

|

25.2 |

Shaft Sleeve(Double Mech.) |

|

25.3 |

Shaft Sleeve(Packing) |

|

26 |

Double mechanical sea |

|

27 |

Packing Gland |

|

28 |

Gland Packing |

|

29 |

Lantern Ring |

|

30 |

Cartridge Seal |

|

31 |

Seal Plate |

|

32 |

Vice impeller |

|

DN |

Ød |

Øk |

ØD |

n |

ØS |

|

32 |

76 |

100 |

140 |

4 |

18 |

|

40 |

84 |

110 |

150 |

4 |

18 |

|

50 |

99 |

125 |

165 |

4 |

18 |

|

65 |

118 |

145 |

185 |

4 |

18 |

|

80 |

132 |

160 |

200 |

8 |

18 |

|

100 |

156 |

180 |

220 |

8 |

18 |

|

125 |

184 |

210 |

250 |

8 |

18 |

|

150 |

211 |

240 |

285 |

8 |

22 |

|

200 |

266 |

295 |

340 |

12 |

22 |

|

250 |

319 |

355 |

405 |

12 |

26 |

|

300 |

370 |

410 |

460 |

12 |

26 |

|

350 |

429 |

470 |

520 |

16 |

26 |

A borehole pump manufacturer plays an important role in water supply systems, especially in areas where surface water is...

READ MOREWater drawn from deep underground plays a key role in agriculture, industry, and residential supply. Behind this process...

READ MOREEfficient irrigation plays a key role in modern agriculture, landscaping, and water management projects. An experienced ...

READ MORE

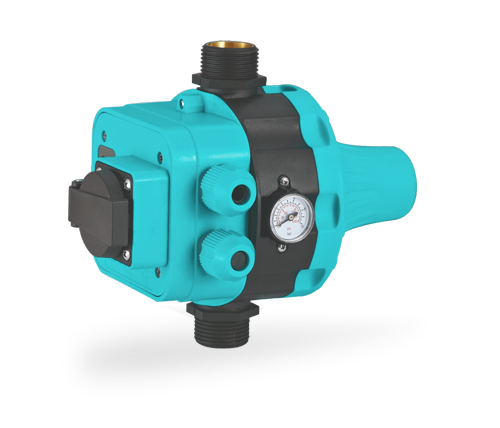

Starting pressure : 1.2bar - 3.0bar Max. Rated Current : 10A Max. Working Press...

See Details

Starting pressure : 1.2bar - 2.2bar Max. Rated Current : 30A Max. Working Press...

See Details

Carbon steel flange Working temperature: -10°C~99°C (Butyl) -10°C~99°C (EPDM) 0°...

See Details

Max. pressure :6bar-16bar Working temperature: -20°C~99°C (Butyl) -20°C~99°C (EP...

See Details

Low Noise Hot And Cold Water Circulation Pump Inlet / Outlet: 2" Body length: 18...

See Details

Rated voltage : 380V Motor power : 1.5kW-5.5kW Intelligent Drainage and Slurry P...

See Details